Chain - that product, consisting of many links. Their shape and method of attachment determine appearance ornamentation. And these parameters also determine the resistance to tensile stresses. But even the strongest chain will break sooner or later, and the probability of this increases when the item is jerked sharply. Accordingly, the ornaments still have to be brought in for repair. Sometimes the damage can be repaired independently. First prepare the tools, consumables. In addition, the question of how to seal a gold chain in a at home. In cases where the repair is complicated, you need to go to a repair shop.

Common causes of damage to gold chains

It is possible to prevent the rupture of a piece, but this requires eliminating all the negative factors that contribute to gold damage and creating conditions for the long-term use of the jewelry. Causes of ruptures, breakages:

- Natural wear and tear of the links: a chain consists of elements that are moving relative to each other, the constant wearing promotes friction of the links, as a result, a natural process of wear and tear of the precious metal develops, in the weakest places the product is torn;

- active use of the clasp: intensive wear of the jewelry, which accelerates the wear and tear of the lock elements, as it has its own resource (determined by the design and characteristics of gold), with frequent wear it decreases, parts break;

- sudden movements: even a new chain can break, the reason in this case, considered an accident, when suddenly hit and jewelry.

What can be repaired at home

Gold brazing is usually performed when defects of a certain nature appear:

- damage to the inside of the product: independently restore the integrity of the product when there is a crack on the front side is more difficult, especially if the links are wide - will be visible solder seam;

- incomplete rupture of one link in a complex weave: most often there is damage to one of the sections, the metal here is bent, broken, it is necessary to return it to its original shape, solder;

- The ring tear on the lock: this area is not conspicuous, it is easier to repair than the chain links - it is enough to perform a soldering seam, and aesthetics in this case is not so important.

Basics of metal brazing: refractory and fusible solder, flux

The temperature at which gold melts is 1064°C. But this value varies depending on the content of this component. To be able to begin the repair, the material is heated. Individual sections are joined using special materials, without which gold soldering is not possible:

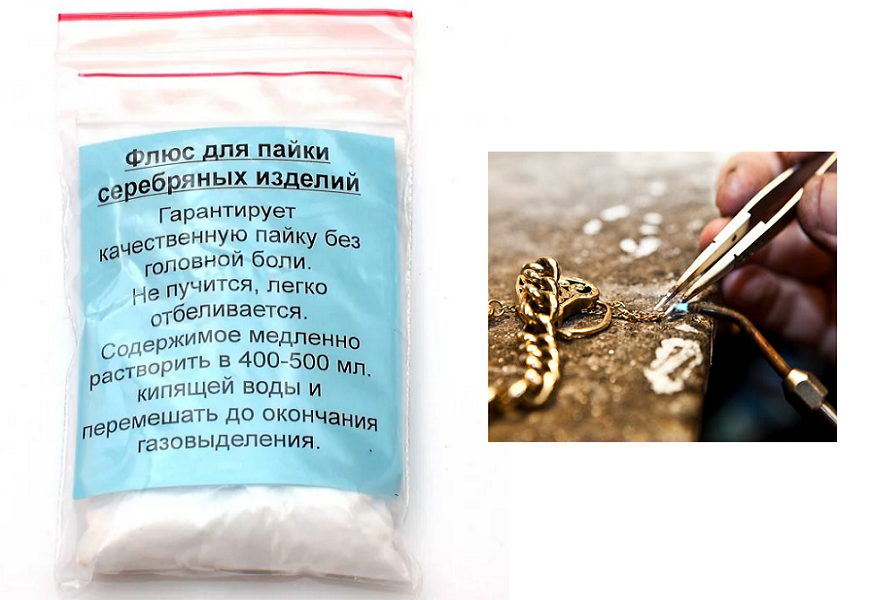

- flux - a composition of several components, used to prevent the formation of an oxide film on the processed material, and also helps to increase the fluidity of solder as it heats up;

- solder - the material is shaped like a wire, it is used to create conditions in which broken metal parts will be joined, it has a lower melting point than that of the gold item being restored.

There are different types of solder:

- easily fusible: changes the structure at temperatures below 300°C;

- refractory: melts when the temperature exceeds the 300°C limit.

And the second variant is characterized by improved characteristics. The material properties are determined by its composition. Light-melting solder most often contains tin, lead, and refractory: copper, silverzinc, gold, etc. But the solder is chosen not only by the characteristics, but also by the color of the material.

It must match the shade of the chain, and therefore use a refractory solder.

The mixture can be made by yourself.

Making standard solder: composition, metal proportions, shape

The composition of the solder differs, which depends on the sample. If you don't have the right size solder wire on hand, you make it yourself:

- Prepare the components for soldering in order to repair 585-carat jewelry. These include gold, silver, and copper, respectively: 585, 115 and 185 parts.

- Metals are melted down.

- Brass is introduced - 135 parts, it can be replaced with cadmium - take 112 parts.

- The melt is poured into the mold, and after the metal cools, the desired shape is given to the product on the anvil (it is pulled out).

Important: It is also possible to make a flux for soldering gold, we need borax (10 g), boric acid (100 g), distilled water (100 g).

Tools for solder preparation

The components of the material are taken in a certain dosage, which is determined with the help of pharmacy scales. Other tools, devices that may be useful in the solder preparation stage:

- a shape that allows you to get as thin a wire as possible;

- containers to determine the dosage of the components;

- burner;

- crucible remeltingThe new product has been designed to be resistant to high temperatures.

Fixing a gold chain yourself at home. The technology of the process

When you plan to do it yourself repair gold chain, it is necessary to adhere to instructions. This will allow you to avoid serious errors (if there is no experience of such work). Main steps:

- Preparing a product that needs to be repaired. The damaged area is repaired, it is necessary to restore the shape of the ring or link that is broken. Then it is fixed with a vise, so that the hand does not shake, and the quality of soldering remains high.

- Clean the metal. It should be further degreased, which will improve the adhesion of materials.

- Flux is applied. It is prepared in advance, because the work must be done quickly (because of the risk of overheating).

- Heat the metal on the damaged section of the circuit.

- Add solder, continue heating.

- Clean the seam, for which you need to remove excess solder.

Important: The thickness of the torch flame can be adjusted, for heating small parts use fevku.

The work ends when the color of the solder becomes the same as the gold being restored.

What you need for soldering at home

When learning the intricacies of how to solder gold properly, you must immediately prepare the tools, techniques for work:

- soldering iron;

- Vise, pliers, or tweezers if small parts of the chain were damaged;

- file - used to clean the weld after soldering is finished;

- gas torch - prepared while the solder is still being prepared;

- The flare is for adjusting the size of the burner flame;

- jewelry drill, polishing equipment.

Consumables are already prepared. If there is no possibility to make solder yourself, you should buy it in advance.

The types are suitable: PSR2, PSR2.5.

Nuances of soldering gold at home

Beginners should learn more about the repair process. You should first practice on ordinary metals, using the proper solder composition. If you start working right away, there is a good chance that the product will be ruined. It is important to learn how to solder gold chain at home: pay attention to the peculiarities of stripping the areas to be joined, and the subtleties of applying flux, the introduction of solder, grinding.

Clean and degrease the surface before soldering

Brazing is the process of remelting metal products of different kinds in a limited area. A high quality weld is ensured if carefully cleaned elements of the product are joined. To remove contaminants, the following are used alkaline solutions, the ambient temperature is +60°C or higher.

Then additionally perform processing of metal with organic solvent.

Apply flux and butt or overlap parts

Torn chain sections can be joined in different ways: butt and overlap. The second option is preferable, it provides a more reliable connection, but can not always be implemented, which is determined by the configuration of the chain links.

Before joining the parts of the product apply flux.

Introducing solder and heating it to the same color as gold

Combustion of components in the solder composition when heated provides the desired result. The parts are firmly joined, and the crack trace disappears. At this stage, the color of the seam, which is formed during soldering of the gold chain, becomes the same color as the basic metal products.

Final sanding with a file, engraver or boron machine

Rough machining is done with a file. There are different kinds of these tools. To ensure a higher quality seam, a jeweler's borer is used. The device can also be used in the future for polishing jewelry, and therefore it is advisable to purchase it for use at home.

The main criterion for an excellent chain link

The quality of the soldered seam depends on various factors:

- The degree of cleaning of the metal before starting the work;

- application of flux;

- solder composition;

- The solder must not be overheated;

- method selection The connection of the metal parts of the chain, this will determine how long the product will last, which means that this is the main factor in assessing the quality of the solder.

Question and answer section

How to solder a gold chain at home with a soldering iron?

- Preparation of the gold product, as well as flux, solder.

- Flux application.

- Laying the solder after heating the gold.

- Connecting the links of the product, the chain on the problem area is fixed butt or overlap. The metal here is heated, which ensures that the connection is secure.

- After soldering is complete, the seam must be deburred and the metal is ground.

How to solder a gold ring at home from improvised means?

When to go to a jeweler

Soldering gold at home is not always possible. Often difficulties of various kinds arise:

- insufficient experience in this area;

- no proper tools at home;

- The failure is complicated, the circuit can not be soldered in the usual way at home.

Most often a craftsman is approached when a chain breaks at sites of complex configuration:

- small chain links in the multi-level weaving: there is a complete break of the link, it is required to perform several stitches instead of one;

- the unique pattern of the product: your experience in performing soldering is not always possible to apply, because the restoration of a rare pattern often requires not just knowledge, but vast experience, multiplied by the talent, which have masters with experience;

- noticeable damage on the outer side: it is much easier to solder the broken sections of the links on the back side, where the seams will not be visible, so that without trace return to place the damaged section and connect the parts of the product on the outside, it is better to contact a jeweler, because he often solders the jewelry in this way.

Repairing jewelry in a workshop

Jewelers use a standard scheme to restore the integrity of the product:

- Preparation of jewelry: cleaning, fixation.

- The choice of flux, solder.

- Soldering. At this stage, workshops use special equipment - laser equipment.

- Cleaning the seam, polishing the product.

To repair silver and gold jewelry should be taken to the nearest jewelry workshop. Salons in different cities:

| City | Name of the workshop | Price, rubles. | Contact |

|---|---|---|---|

| Voronezh | "Yuvelir-Service | 250-350 | +7(473)292-52-92 |

| Novosibirsk | "Master Jeweler | from 350 | +7(953)877-05-55 |

| Chita | "Jewelry Workshop" | from 200 | 8(3022)31-59-76 |

| Smolensk | "Jewelry Workshop" | from 250 | +7(920)324-68-69 |

| SPb | ARTEL | from 850 | +7(812)982-88-78 |

| Samara | "Jewelers of Samara" | from 170 | 8(927)201-32-23 |

| Yekaterinburg | Shubin Service | After a preliminary assessment | +7(343)361-35-11 |

| Moscow | Nota-Gold | from 900 | +7(495)135-00-10 |

| Bryansk | "Master Jeweler | from 250 | +7(910)337-65-51 |

| Barnaul | Diamond gold | 300 | +7(913)239-89-89 |

Advantages of laser soldering at the jeweler

Positive qualities of technology:

- high accuracy;

- the small radius of the light point;

- performing soldering in areas where access to the broken part is limited;

- no metal stress effect;

- increasing corrosion resistance;

- no need to use filler material;

- the possibility of soldering coated products without the risk of damaging it.

Factors for estimating the cost of work

Prices in jewelry shops are formed taking into account factors:

- the size of the area to be repaired;

- the degree of urgency of the product's recovery;

- configuration of the jewelry: whether there is an intricate weave, etc.;

- adding another dose of gold to correct complex defects.

Care and wear of restored jewelry

Recommendations:

- You cannot go to bed without taking off your jewelry;

- jewelry should be kept in a sealed box with padding inside;

- It is not recommended to take a shower or a bath with a gold chain around your neck;

- It is forbidden to play sports, visit the sauna in jewelry;

- The product is cared for from time to time.

Video: Features of soldering a gold chain at home

Jeweler's comment