Sometimes everyday things hide real treasures in their compositions. The objects around us can contain a wide variety of elements.

How much precious metal contain electronic components? How separate out the gold from other metals at home? Is it possible to get gold from old electronics? What is the least expensive way to mine?

Let's look at all the questions in detail.

The use of gold in electrical and radio engineering

Because of its characteristics, gold is a sought-after material for use in various electronic devices. It is highly electrically conductive, does not tarnish like copper or silver, and does not deteriorate over time. In addition, gold - is a soft material that easily takes any shape.

The most popular gold metal in the production of electrolytic coatings, contacts, connections. The next most popular application is the creation of gold interfaces in semiconductor components.

In recent decades, more than 1,000 tons of precious metal have been used in electrical and radio engineering.

Gold Mining from radio components is a labor-intensive process. The metal undergoes refining to separate it from other elements.

Radio component catalogs and equipment data sheets as sources of information on precious metal content

LearnYou can find out whether or not there is gold in radio components by reading the data sheet. The datasheet, among other information, contains the composition and date of manufacture of the product. Such catalogs are now available for free download, most often in the form of tables.

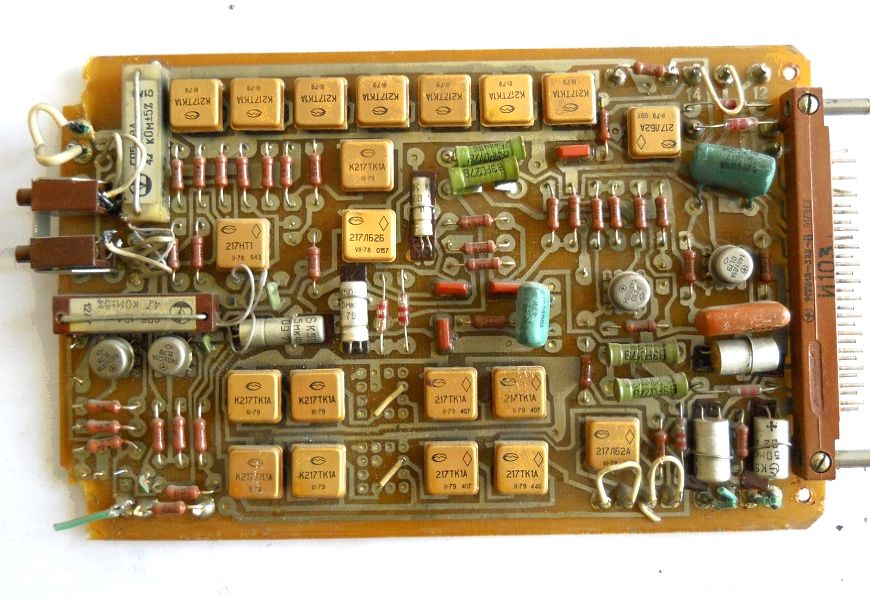

The most common way to find precious metal is inside Soviet radio components. It was used to coat the pins of microcircuits, connectors, the grid of radio tubes, and the substrates for the conductors inside transistors.

Solar metal is less common in modern technology and is usually replaced by tungsten.

As for the USSR technology, the content of the precious metal inside the chips can be as high as 5%. Most of all gold metal The Soviet Union never saved money on this industry.

Legality and terms of extraction of gold from old equipment for profit under the 41-FZ

The law states that the activities of processing scrap and waste precious metals are subject to licensing under the legislation of the Russian Federation.

IEs and legal entities have the right to buy and process the remains of precious metals with a certificate from the Assay Office.

If you try to sell the metal, independently obtained from radio components, to fence traders, you may be criminally liable. Extracting precious metal from gold-containing elements without permission - not legal.

Penalties under the CAO

Illegal extraction can lead to an administrative fine. Article 15.44 of the CAO states: the amount of the fine will be one or one and a half times the value of the materials that are the subject of the offense.

Why gold in radio components is more valuable than silver

Contrary to the fact that silver is more affordable and also has better electrical conductivity, it is the solar metal that is favored in production. It takes a long time to oxidize, which prolongs lifespan details.

There are not many products that include silver metal. The most rich in this metal are connector contacts, resistors, transistors, diodes, capacitors, and relay contacts.

Silver is sometimes difficult to obtain, so it is often impractical.

List of radio equipment and gold-containing elements installed before 1985-1986

Soviet electronics produced before 1985-1986 deserve special attention. Such devices contain the maximum amount of precious metal, so you should not be in a hurry to part with old Soviet-era equipment.

Many devices, such as televisions, tape recorders, radios, contain gold "stuffing.

The list of gold-containing parts of radio equipment will be as follows:

- Transistors. A large amount of precious metal content is found in the KT101, KT103, KT117, KT603, KT613 series, with its main concentration under the crystal or on the legs.

- Connectors. They are coated with the thinnest layers of solar metal.

- Radio tubes. Especially different models GMI-11, 12P17L, 6V1P. Radio tubes, in addition to gold, can contain platinum, silver, tantalum, palladium.

- Semiconductors. A little precious metal is found in diodes, LEDs, and stabilitrons.

- Condensers. It is these that contain the largest volume of solar metal.

- A wristwatch. Gold sometimes covered the body of the product.

- Computer parts. Gold-containing parts can be in processors, connectors, etc.

The older the Soviet item, the more valuable materials may be inside. The metal used in radio components is 999 proof. The thickness of the gold cladding on radio components is extremely small and measured in microns.

List of modern devices with gold

If you compare it with Soviet equipment, modern devices contain much less gold metal. However, there are electronic devices that are in no way inferior in these indicators to Soviet-era equipment.

For example, the popular HP Laser Jet laser printer contains about a gram of precious metal per composition.

Among the modern devices of interest in terms of gold mining:

Microcircuits

Solar metal is found in almost all microcircuits. It will be present as gold-plated pins, whose quantity is equal to 1/3 of the mass of the chip.

Semiconductors

Gold is found in diodes, stabilitrons, thyristors and optocouplers.

SIM cards

The SIM cards that have become part of our daily lives contain a grid of gold. It would take about 2,000 to 2,500 SIM cards to produce 1 gram of gold.

Computer parts

Metal is found on connectors, case pins, memory slots, contacts, sometimes - inside the power supply, cooler, keyboard panel. The predominant presence of gold is in the boards.

Modern computers typically contain less than 40 grams of precious metal.

The least contain Cyrix Cz486, IBM 5×86C, 486 DZ2-80, 486 SD processors - up to 6 grams. Intel i435 DZ4, ADM, Pentium PR - up to 12.5 grams.

Two ways to extract gold from machinery. Step-by-step instructions

How to extract gold from radio components at home? There are many different techniques available. Let's consider particularly effective and widespread - affinity and physical.

Physical (electrolysis) using hydrochloric acid: pros and cons

The physical methodology is quite complicated. It requires gold chloride, hydrochloric acid, and precious metal of the highest purity, which is used as the positive electrode. Iron or lead is used as the negative electrode.

A steady current is connected to the electrodes for the desired effect. The density of the current indicates dissolution in an electrolytic reaction. A drop in density will tell you that the metal is completely dissolved.

The disadvantages of the electrolysis method include the fact that it is only suitable for copper and brass products, is quite costly, difficult to implement.

Chemical: Refining with Tsar Vodka

It is possible to etch the solar material using its inert characteristics.

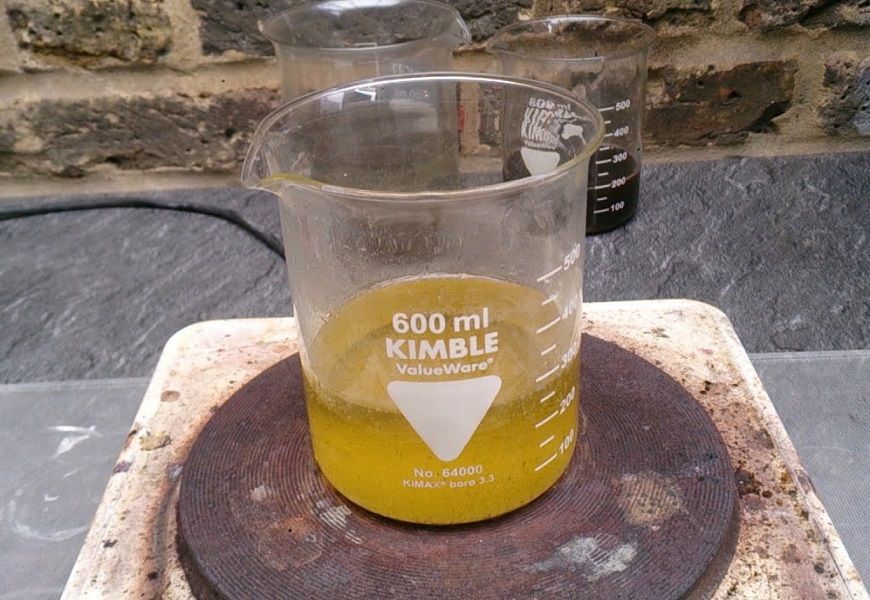

Tzar's vodka is a mixture of saturated nitric and hydrochloric acids (1:3). It is the strongest oxidizing agent used to separate precious metal from other impurities.

Let's look at step-by-step refining using acids.

Piece by piece

First, the radio components with gold are completely disassembled, sifting out the elements that have no value. Grinding the remaining components improves the flow of the process. If this is not done, the final solution is highly contaminated and requires additional cleaning.

Component firing

The elements should be burned. This will help get rid of organics.

Preparing a mixture of hydrochloric acid and nitric acid in the ratio of 1: 3

Now it is time to proceed to the preparation of the essence of royal vodka. The combination of the components should take place the day before use.

The formula for royal vodka is a compound of HNO₃, HCl and H₂O.

The solution should turn a yellow-orange color.

Heating parts in acid on an electric stove

Crushed radio components containing gold are immersed in the essence. The essence is heated on an electric stove.

Important: The volume of the essence of royal vodka must necessarily overlap the mass of the materials by a factor of three.

Soaking for 6 hours

The mixture will need to be left for up to 6 hours. This is enough time for the precious metal to precipitate.

Introduction of 0.5% hydroquinone into the solution

After dissolving in the essence, the precious metal will precipitate as tiny invisible particles. Now these particles must be isolated from the entire mixture.

To do this, you need to add 0.5% hydroquinone to the solution, its composition is 5 grams of the active substance to 100 grams of water.

The resulting mixture is gently added to a common container.

Stiffening for another 4 hours

Now the elements are stirred and left for 4 hours.

Drain the liquid and dry the sludge

If the whole algorithm is performed correctly, then at the bottom of the vessel there will be a golden sediment. The liquid has to be drained off, and the rest is evaporated and dried.

Alloying gold in a crucible on a burner

The final step is to fuse the solar metal. It is recommended to use a special crucible and a burner for the procedure.

Sometimes mercury is used instead of vodka and then evaporated.

Also, to etch the precious metal from the surface is realistic with iodine.

Refining without heating for 7 days

AffinityIt will take about a week for the heating to work. The instructions are as follows:

- A special essence is prepared and the parts are immersed in it. The composition of the essence is hydrochloric acid and hydrogen peroxide (2 to 1).

- The entire solution must be stirred gently every day. The course of the reaction separates the gold from the other components.

- After 7 days, after separation of the precious metal, the liquid is filtered and the precipitate is washed with methyl alcohol.

- The sludge is dried and then remelted.

Pros and cons of the chemical method

Safety precautions

The precautionary measures are a must when recovering gold from radio components.

Work with open windows and good ventilation

Refining releases vapors of substances harmful to humans, inhalation of which leads to deplorable results and even death.

Experimentation indoors is only possible with good ventilation systems.

Protective clothing and goggles

Vapors can affect the organs of vision, and accidental contact with the skin causes burns.

Overalls and goggles should be as important a part of the whole process as the gold elements.

Rules for working with acids. First aid in case of burns

Saturated acids should be stored in a tight container on a pallet. Acids may only be overflowed inside the fume cupboard.

Acid causes severe chemical burns when in contact with skin. The affected area should be rinsed with water for at least 20 minutes. Next, apply a baking soda dressing made of a 2% soda solution. After the compress is removed, and the affected area is wiped dry. A follow-up visit to the doctor is mandatory.

Actions in case of a solution leak

If the solution leaks due to negligence, cover the spill with sand. Sand that has absorbed chemicals should be collected using gloves, then disposed of.

Next, the flooring will need to be treated with a solution of soda, and then - rinse with running water.

Video: Gold from radio components by refining method

Subject: Q&A

I want to buy up equipment to extract gold from it. Do I need to register my business?

The work of buying companies is licensed and monitored.

What other metals can be mined if you etch them out of machinery?

You can extract platinum from some parts by using nitric acid.

How do I remove gilding from radio components at home?

250-350 grams of electrolyte and 100 grams of nitrate are poured into a vessel. The components are stirred until the nitrate is dissolved. Parts cleaned from iron beforehand are immersed in the solution. The container should be heated.

Once the reaction has started, the vessel is placed in a shady place. After half an hour, the gold will become a film. It is removed by straining, and the extracted precious metal is dried.

How to extract gold from microchips at home?

Then the liquid is strained, and the sediment is cleaned with water or alcohol.

The powder obtained after washing is extremely brittle. It will have to be dried and smelted.

The answer to the question "how to extract gold from microchips?" is to follow the instructions and precautions.

Which radio items contain the most gold?

Jeweler's comment