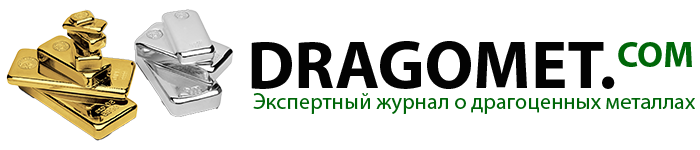

Czar's Vodka - water of kings - Aqua Regia in Latin is a mixture of two acids combined together. Nitric and hydrochloric acids are taken in the proportion one to three. It is a mass balance, in terms of pure substances one to two. It gives off an unpleasant chlorine smell. A unique feature of this composition is the ability to dissolve a number of precious metals, such as gold, platinum, etc. It is used for purifying gold from impurities by filtering and metal deposition.

Tsar's Vodka: History of the Name, Acid Proportion and Chemical Properties

The properties of Aqua Regia were described even before hydrochloric acid was discovered in the 14th century. The compound was widespread and received its name during the heyday of alchemy on the European continent. The German alchemist Albert the Great (of Cologne), who was the mentor of Thomas Aquinas, called it aqua secunda as derived from aqua prima, nitric acid.

Latin for "secondary vodka" and "primary vodka.

Representatives of the alchemical cohort began to refer to it as royal when Cardinal Bonaventure, regarded by Catholicism as one of the church fathers, established that a substance that combined two acids was capable of dissolving the "king of metals. Prior to this point, it had been believed that the noble metal could not be altered by anything. The interaction of royal vodka and gold proved the opposite. In Russia, M.V. Lomonosov called the solution "royal vodka.

The symbol of Aqua Regia, adopted by the alchemists: ▽R. inverted triangle - the sign of water.

The chemical products combine to form a product composition that is highly active. This is manifested by a strong odor with hints of chlorine and nitrogen dioxide. The gaseous nitrogen dioxide is yellow in color and resembles smoke of this tone.

At first, royal vodka has no color, but gradually acquires a yellow-orange hue, becoming a very strong oxidizer. If stored for some time, it gradually decomposes, releasing gaseous substances.

The etching rate, that is, the oxidation, or solubility level, of gold is about 10 μm/min. Other noble metals require heating to certain temperatures to pass the reaction. This is true of rhodium and iridium. Other metals have different properties, such as silver. Dissolution in Aqua Regia does not occur, a layer of AgCl, precious metal chloride, is formed on the surface.

What is the composition of royal vodka to dissolve gold and what reaction is possible at home

The exact weighted composition of the two acids is described as 65-68% by weight HNO3 and 32-36% HCl. Equation of the reaction that occurs when etching gold metal in a double solution of acids:

Au + HNO3 + 4 HCl = HAuCl4 + NO + 2 H2O

Bottom line: hydrogen tetrachlorate (hydrogen gold chloride), nitrogen oxide, water.

From the composition of hydrogen tetrachlorate, it is clear that the compound is between gold and hydrochloric acid. Nitric acid is present in the process as a catalyst with oxidizing properties.

The whole process takes place in three stages:

- Dissolving gold in royal vodka.

- Filtration of the resulting solution.

- The process of gold precipitation after evaporation.

Safety rules for working with chemical reagents

Home chemistry lab for refiners The process, similar to alchemical procedures, requires the utmost care and concentration.

Cleaning The process takes several hours and involves the evaporation of toxic gases such as NOCl, Cl, Cl2, NO, NO, and NO. The process lasts several hours, with toxic gases NOCl, Cl2, NO, NO2. This means that everything must take place either outdoors, or in a room that is well ventilated, or a powerful exhaust ventilation system is arranged.

You must protect your eyes with special goggles, your face with a respirator, and your body with appropriate protective clothing. No reagents should come into contact with body parts or the face.

The importance of meeting deadlines and proportions

In order for the reaction to be successful, the correct proportions must be observed: 65-68% HNO3, to 32-35% HCl.

To obtain 1 g of gold, about 5 g of the reagent or 3.75 milliliters of hydrochloric acid would be required. This proportion is derived from the chemical formula for producing hydrogen tetrachloride. When working with scrap precious metal, in order to maintain the proportions, before dipping it into the acid solution, you should pass a magnet over it in order to remove metal particles that have ferromagnetic properties.

Further processing of raw materials is carried out by chemical methods.

Pre-treatment of gold in nitric acid

One of the methods of cleaning scrap gold or items containing the noble metal - cleaning nitric acid. It removes almost all accumulated impurities.

The gold is then dissolved using hydrochloric acid.

The procedure of dissolving metal in acids and its gradual evaporation

The mechanism of the etching reaction is triggered by heating the mixed solution and adding nitric acid, which catalyzes the process. When all the metal has dissolved, it is no longer added, but the mixture is allowed to stand for about half an hour. After this comes the filtration stage. For this purpose, filter paper of different quality comes in handy. Iron sulfide is often added to the filter - FeS.

After this, the mixture is allowed to "rest" for half an hour. During this time, some of the volatile elements will be gone, and the evaporation process can begin. This process is carried out under the influence of sulfuric acid. It is added in such a way that for 5 parts of it 100 ml of the solution.

Acid provides precipitation of silver, lead, aluminum and zinc, if they still remain after filtration, and removal of nitric acid.

Evaporation is carried out slowly with slow heating, avoiding boiling. HCl is added to the initial state and then H2Oh, the proportion is 1 to 1. Then Composition It takes 24 hours for the silver to precipitate to the bottom of the container.

Chemical equation for calculating the proportions of acids: nitric, hydrochloric and sulfuric

During the etching process, the proportions of acid content must be maintained at all times. To obtain 1 gram of gold, about 5 grams of reagent or 3.75 milliliters of hydrochloric acid will be required. The addition of nitric acid to hydrochloric acid is done as a two to one ratio.

Sulfuric acid is added at the evaporation stage with 5 ml per 100 ml of solution.

There is no exact equation, because the conditions of each stage of the dissolution, filtration and evaporation process may vary somewhat.

Precipitation of gold using different reagents over a 24-hour period

After the evaporation stage, it is time to precipitate the gold metal from the solution. This is carried out using one of the chemical reagents:

Top 5 substances for gold deposition

- Hydrazine is a strong solvent, not very suitable for the home laboratory, if it is still used, add it drop by drop, otherwise it can explode;

- iron sulfate; FeSO4, it is added with an aqueous solution, the ratio of 1 to 2.

- oxalic acid is not very suitable for primary precipitation, but it is successful in secondary precipitation;

- Sodium pyrosulfite is suitable for secondary precipitation, added in pure form, requires caution: if something is done wrong - there will be a release of harmful gaseous substances;

- hydrogen peroxide must have a high concentration for the process to work.

If the procedures are done correctly, the gold will precipitate as a red or orange heavy precipitate. It will concentrate at the bottom of the container.

Reaction formula with iron sulfate (HAuCl4 + 3FeSO4 = Fe2 (SО4) 3 + FeCl3 + HCl + Ats)

The precipitation of gold from royal vodka based on the addition of iron sulfate, is described by the formula:

HAuCl4+ 3FeSO4 = Fe2 (SO4)3 + FeCl3 + HCl + Au

Divalent iron sulfate is required at least 13 g per 1 g of metal that is planned to be obtained. Observe the reaction: the solution should become cloudy, if this does not happen and a hiss is heard, it is a sign that the nitric acid has not been completely removed. Then the evaporation process is repeated with the addition of more sulfuric acid compound iron sulfate. This is a safe way to remove traces of nitric acid during the recovery phase.

Substances that can harm the gold recovery process

In addition to the described reagents that contribute to gold precipitation, there are still a few that can be effective in individual, special, cases, but with the standard Affinage will not help or will have a detrimental effect.

This:

- Potassium cyanide only works if you need to recover metal from chloride gold;

- ammonia hydrate and ammonium carbonate are hazardous to human health, and in addition, you get "rattlesnake gold", which can explode;

- mercury nitrate is fraught with health and life-threatening vapors;

- citrate, tartrate, and potassium acetate are useless for obtaining gold material with royal vodka.

You should not experiment with these substances.

Final washing of gold precipitate in acid and ammonia solution

When the gold has settled to the bottom in the form of pieces, large drops, and sand, the solution is carefully drained. The metal material is washed first with hydrochloric acid and then with ammonia. These procedures are needed to remove copper residue.

At the very end, the hot water will remove the ammonium hydroxide particles and bring the gold back to its proper appearance.

Melting gold sand in a crucible to produce 999 gold

The resulting placer golden pieces can be reduced to a pellet state or melted as an ingot or bar. A crucible that is treated with sodium tetrocarbonate before heating comes in handy for this purpose. This will promote a better flow of gold on the walls along with cleaning the vessel of oxides.

The melting point of the precious metal is 1063 degrees C. Because the burner provides a lower combustion temperature, the vessel and the material itself are treated with Borax. It reduces the amount of heat required to melt.

It's a way of getting 24-karat gold from scrap or gold-containing products.

Video: Is there a lot of gold in your gold. Extracting gold chemically

Question and answer section

How to make royal vodka to dissolve gold?

How to precipitate gold from the king's vodka at home?

- iron sulfate; FeSO4 is added with an aqueous solution, proportion 1 to 2;

- oxalic acid can be successfully used in secondary precipitation;

- Sodium pyrosulfite is suitable for secondary precipitation, added in pure form, in aqueous solution, requires caution: if something is done wrong - there will be a release of harmful gaseous substances;

- hydrogen peroxide must have a high concentration for the process to work.

- Hydrazine is a strong solvent, not very suitable for home environmentIf it is used, it should be added in small drops, because if it is used carelessly, it can explode.

How to recover gold from royal vodka?

The craftsmen offer another way to extract gold from various radio components - transistors and others. It consists in using "poor" royal vodka without acids. This method is based on a technology in which the active components are battery electrolyte, iron sulfate and ammonium nitrate. A small yield of gold is obtained, whose grains can be weighed on an electronic scale to see how much it is.