Silver found inside a variety of electronics much more often than others precious metals. It surrounds us everywhere, which is why its extraction attracts both those who are just starting out in the Refiningand experienced miners alike. For beginners it will be useful to learn how to extract silver from radio components in at homeI'd like to know what kind of sample it might be, and what to do with it next.

The use of silver in electronics. Technical silver in the USSR

Silver conducts electricity and heat better than other metals. It is inert to water, air and some gases. It is used in a wide variety of industries, the list of which is constantly expanding.

Precious metal is used to create jewelry, in the production of contacts for various electrical products, for minting coins, as an investment vehicle, in the manufacture of mirrors, clothing, batteries, in the chemical industry, and in photography. The volume of lunar metal accounted for by the industrial sector exceeds 70% of the global production.

In the era of the USSR, they did not skimp on silver in the production of radio components. The metal used in this field is called technical. It is a special alloy containing copper, nickel, tin, aluminum, and cadmium as impurities. The amount of additives is not great, usually not more than 0.2% of the total composition. The bulk of it is pure silver.

Magnetic and non-magnetic samples of technical precious metal are an exception. Here the silver content varies from 60 to 80%.

If jewelry metal performs a decorative function, the technical metal must provide electrical conductivity and light reflection.

There are reference books available online for free, from which you can learn information about the materials that make up electronics.

List of silver-containing components in electronics

The main sources of silver recyclables for refining are devices from the radio and electrical fields. In addition to the lunar metal, devices may contain gold, palladium, tantalum, platinum.

Soviet microcircuits

The greatest amount of silver plating is found on chips manufactured before 1990.

If we compare these Soviet parts with others, they are quite promising for refining. The most lunar metal per 1,000 units of microchips contain:

- 1200CL2 is about 120 grams;

- 1200CL1 is about 114 grams;

- The 1200M1 is about 90 grams;

- K57ZRF41/42 - about 70 grams;

Electronic machine capacitors

Capacitors can be found inside computing devices, tube televisions, tape recorders, and telephone exchanges.

Significant amounts of precious metal per 1,000 pieces contain:

- ETO-4 600*10 - 14163.6999 grams;

- ETO-4 - 8345.16 grams;

- ETO-3 400*2 - 2,450 grams;

- ETO-3 - 1655.07 grams;

The cost of one capacitor varies from 50 to 5000 rubles.

Radio Resistors

The most prized were variable resistors whose copper leads were treated with sterling silver.

The prevailing amount of precious metal per 1,000 units contains:

- UN-100 - 207 grams;

- UNU50 - 132 grams;

- UH 25 - 67 grams;

Domestic and imported connectors

Connecting elements are used to make a temporary connection of electrical conductors by means of mechanical contact.

Imported connectors are less preferable for refining because they are three times less precious metal than the Soviet ones.

A lot of moon metal can be obtained from connectors:

WG1H-2-31

WG90-5 (socket)

RMG-39B45SH2A1

WG1H-2-23

WG1H-2-29.

Transistors

A transistor is a semiconductor electronic component used to amplify, generate, switch, or convert an electrical signal.

Usually transistors are purchased for extraction gold, but some models different with higher lunar metal content. These include 2T935A, 2T944A, 2T945A, and 2T998A, which contain from 270 to 520 grams of silver per 1000 units.

Other Soviet-era electrical appliances

There are many other devices hiding real treasures in the lineup. Among them:

- film;

- LEDs;

- switches, buttons;

- generator lamps;

- rel.

In addition to electronics, silver can be extracted from scrap silverware, jewelry waste, silver solder.

Chemical properties of technical silver

The term "technical silver" itself applies to secondary precious metal from hardware recycling and to material used in engineering.

The properties of lunar metal that have contributed to its widespread use are ductility, high reflectivity, and increased chemical stability. The metal does not react with oxygen, hydrogen, nitrogen, carbon, and silicon.

Technical silver melts at temperatures between 780 and 962 оC, boiling at 2210 оС.

3 ways to extract - refine silver at home from radio components

How do you separate silver from contacts at home? The answer comes down to the three most common ways.

Mechanical impact

This treatment is the easiest way to do it. The method is suitable for some types of contacts that can be separated with pliers or pliers.

Thermal effect

This method is used when mechanical extraction is not possible. A soldering iron or gas torch can be used for thermal treatment.

When exposed to extreme temperatures, the silver elements can easily be unsoldered from their holders. The blade of a knife will do the job of removing the elements.

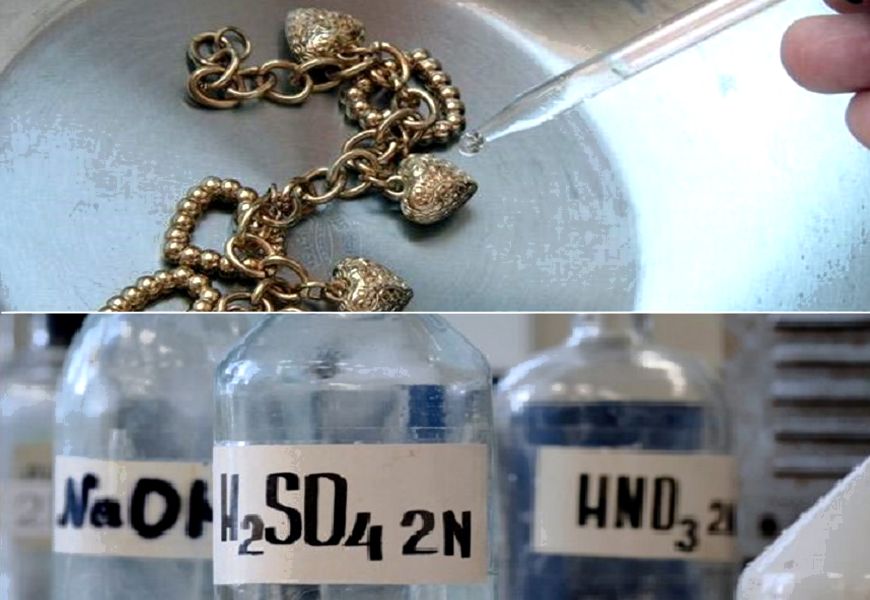

The chemical method

Chemically is called the treatment of technical parts with nitric acid. It is hardly used in industry, the main area of application is laboratory practice.

The precious metal dissolves to form silver nitrate and nitrogen oxide. The formula is as follows:

3Ag + 4HNO3 = 3AgNO3 + NO + 2H2O

Let's take a closer look at the refining process.

Preparation of tools and mortar

How to extract silver from radio components with nitric acid? First of all, you need to buy the right tools and reagents.

For the job you need:

- quartz stick;

- glass vessel;

- copper;

- 8% nitric acid essence.

Important!

Acid solution can be obtained by mixing it with deionized water in a 1 to 1 ratio.

Safety precautions

Extraction of silver from contacts in the home requires precautions.

- Refining should take place in a well ventilated room or outdoors, as vapors will be released into the air that are harmful to humans.

- For work it is necessary to buy protective clothing that will cover the entire body, goggles with an elastic band, respirator.

- Store saturated acids in a tight container on a pallet. Acids may only be poured inside a fume cupboard.

- Acid causes severe chemical burns when in contact with skin. The affected area should be rinsed with water for at least 20 minutes. Next, apply a baking soda dressing of two percent baking soda solution.

- When melting precious metal, it is necessary to observe fire safety.

Important!

The key when mixing saturated acids with water is that acids are added to water, not the other way around.

The extraction process

First, the diluted acid must be stirred with a quartz stick. The necessary amount of acid is calculated as one liter of essence per 50 grams of precious metal.

Important: Excess nitric acid will lead to the release of a red precipitate - nitric oxide.

Now the silver should be placed inside the vessel with the acid. The dissolving process will start, which can last up to 12 hours.

After the metal is dissolved, copper will need to be added to the solution.

Copper deposition

Copper helps accelerate the displacement of the precious metal. A silvery, concrete-like coating will begin to form on its surface. The solution will darken.

To maintain the rate of reaction, it is advisable to periodically clean the surface of the copper objects from the silver plaque.

When the process is completely finished, all the liquid inside the vessel cools down, the signs of a displacement reaction are no longer observed. The silver will fall to the bottom as a gray layer, and the essence will become clear.

Now you can start filtration with a funnel, a filter, and a clean container. The procedure is carried out repeatedly in order to reduce the loss of the precious metal.

Melting silver

Before fusing, the metal must be pressed so that it does not fly off under the burner jet. A metal tube or bolt is good for pressing.

You can melt the metal into a small ingot using a crucible. The crucible can be purchased in a specialized store or you can make your own from refractory materials. In this case, the crucible must be sprinkled with borax.

The crucible is heated with a gasoline or gas stove. The borax is added as it melts, this will prevent the silver from burning out.

Other methods of silver smelting

There are other methods of refining silver From radio parts. These include:

- Electrolytic;

- Kupeled;

- Acid-free method;

Extraction from low-grade alloys

Low-grade alloys have a lower melting point. For their refining, they resort to cuperization. Cuperfining is based on the property of lead, melted with silverThe metal is not a material that can be used in the same way as it is used in the same way as the metal.

The method requires a melting furnace and a crucible shaped like a bowl.

The furnace is covered inside with marl, a special porous clay capable of absorbing lead oxide.

The disadvantage of cupping is that when finished, the silver alloy will contain more impurities.

Step by step, the process is as follows:

- A crucible with technical precious metal and lead is placed inside the preheated furnace.

- The materials remain inside the furnace until they are completely melted.

- The crucible is removed from the furnace with tongs and the liquid material is poured into the prepared molds.

Electrolytic method

The electrolysis method is based on the properties of an uninterrupted electric current. This is what allows the charged silver elements to move from the negative electrode to the positive electrode.

Silver parts are used as the anode, and a silver plate is used as the cathode.

The electrolysis method requires:

- Clips;

- Power supply up to 5 watts;

- Capacity;

- An electrolyte is a liquid that transmits current. It can be obtained by mixing ammonium nitrate with water;

How to remove silver from the contacts with this method? The algorithm is as follows:

- The clamps connect the scrap silver to the anode.

- A silver plate is connected to the cathode.

- The power supply is connected to the mains.

- The positive electrode will collect precious metal, which can then be smelted into an ingot.

This method does not require the use of a large number of reagents and is suitable for the process at home.

Important: Excessive current can cause blackening of the silver.

In addition to these refining methods, there is the chlorine method. It is based on the property of silver and base metals to oxidize under the influence of chlorine.

Clear It is not easy to alloy with this method at home, but chlorine is actively used in specially equipped plants.

Question and answer section

How do you get pure silver from silver contacts?

The choice of cleaning method depends directly on the amount of recycled silver, its condition, and the availability of the necessary equipment.

How do I remove the silver from the contacts of the starters?

Technical parts are immersed in the diluted acid; the process of dissolving the precious metal can take more than 12 hours. Next, the lunar metal is displaced with copper. This stage takes up to three days.

How to extract silver from contacts at home?

The essence is then evaporated to a dry residue, fused with a gas burner, and dissolved again. The work is repeated until a pure metal is obtained.

How do I separate the silver from the copper on the contacts?

The resulting ingot should be dissolved in hydrochloric acid to precipitate the remaining elements. The residue is removed by filtration, calcined, and dissolved again. The procedure is carried out repeatedly.

After separating all unnecessary impurities you get pure silver.

How do I remove silver plating from radio components?

Note that the electrolyte must be changed periodically because it will accumulate copper.

Production realization

Do not forget that the processing of scrap and waste precious metals are subject to licensing under Russian law.

IEs and legal entities have the right to buy and process the remains of precious metals with a certificate from the Assay Office.

If you try to sell the metal, independently obtained from radio components, to fence dealers, you should learn about the criminal responsibility for illegal mining and sale.

Violations are regulated by Article 15.44 of the CAO, which states: the amount of the fine will be one or one and a half times the value of the materials that are the subject of the offense.

Cost of different samples

The value of any sample depends on the price of pure precious metal set by the Central Bank of Russia. To determine the current value of a sample, you need to multiply the current price of the highest alloy by the required coefficient.

Current sample cost for the year 2021:

| Sample | Cost per gram, rubles. |

|---|---|

| 999 | 37 |

| 960 | 35,5 |

| 925 | 34 |

| 875 | 32 |

| 830 | 30 |

Silver from radio components is usually 999, 960, 875 proof.

Sales locations

Buyers should look for thematic forums and sites, among private ads. Pawnshops and pawnshops accept such metal several times cheaper than its real value.

If you do not have a license allowing the extraction of precious metal from recycled materials, you can try to make simple jewelry from the silver obtained.

Video: technical silver. ways to remove silver from contacts

Jeweler's comment