Roding Gold is the deposition of a layer of another material, which also belongs to the noble metal group, on the surface of precious metal items. This material is the chemical element Rhodium. The film is deposited by spraying up to 25 microns thick, giving the product a silvery-white or black hue.

What is rhodium: physical and chemical properties of the metal. Rhodium plating of gold - what is it and why, what is the procedure

Rhodium (Rh) is obtained industrially by the processing of native platinum; it belongs to the platinum group. It was discovered in the early 19th century by the English chemist William G. Wollaston, and was named by him by analogy with the ancient Greek name ῥόδον (rhodon) - rose, because the compound of the metal with other elements tends to have different shades of dark red color. In Latin it is called Rhodium.

Rhodium is an expensive metal and is produced in small quantities around the world.

Rhodium's physical properties are slightly reminiscent of aluminum, it is hard and brittle and has a bluish-white color. Its properties are:

- durability;

- malleability;

- high reflectivity;

- resistance to temperature effects.

Chemical characteristics of the metal:

- high stability in interaction with other elements;

- inertia;

- low oxidizability.

These properties allow to target the effective and efficient use of the material in several directions: as a catalyst in the chemical industry and automotive industry, as a construction material in the manufacture of glass products, mirrors for lasers, and high temperature gauges.

Rhodium holds a special place in jewelry. It is used to coat gold and silver jewelry.

The effect of rhodium plating on jewelry. What is rhodium-plated on gold

Gold is coated with a film of rhodium for aesthetic reasons, as well as to give special properties to products.

Rodinated yellow gold takes on a peculiar appearance comparable to that of white gold. Moreover, the plating is applied to the base metal of any grade starting from 585. Regardless of the original color of the precious metal, which is yellowish or reddish, it becomes radiant with a silvery-steel hue. White gold, which has a characteristic yellowish shade, acquires a perfect white color after rhodium plating.

The radiant appearance of the surface with a particularly durable coating distinguishes it in appearance from the characteristics of jewelry made in the traditional way. This variant of treatment of rings, earrings, rings, chains, bracelets is gaining its admirers. Gold rhodium-plating emphasizes the brilliance and beauty of precious stones.

Rhodium treatment of a white or transparent stone, such as a diamond, visually increases its size. In addition to its design qualities, the rhodium treatment increases the durability of the jewelry over time.

Purposes of rhodium-plating

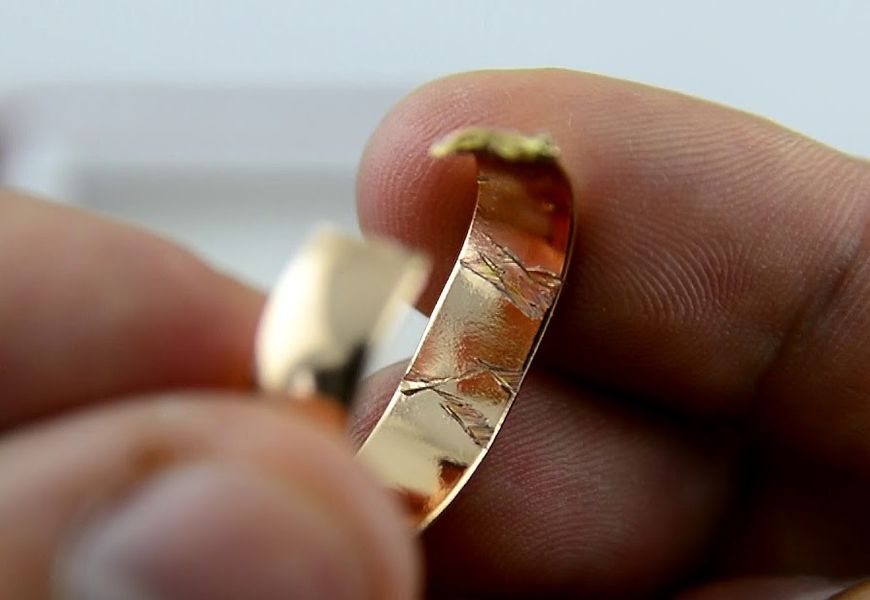

Rhodium plating makes the surface of the jewelry stronger and resistant to deformation, scratches, or minor cracks. The same is true of silver: rhodium-coated jewelry is protected against oxidation and the appearance of a characteristic black plaque, retains its luster, and does not tarnish.

The main uses of rhodium plating:

- giving a certain hue to the jewelry;

- treatment of places where gemstones or other design elements are inserted;

- technological feature of the coating - strengthening the clasp, the most susceptible to deformation and wear.

Pros and cons of this procedure

Gold items coated with a layer of rhodium film are more resistant to wear and tear and less susceptible to atmospheric influences such as temperature. The hardness of the material is increased, as gold in its pure form is a rather soft, ductile metal that is easily deformed.

This also applies to antique jewelry. To make them last longer, you can have them rhodium-plated at a jewelry shop.

Despite its positive qualities, rhodium plating can fade with time, so your jewelry needs to be cared for with care and attention. You can extend the life of your jewelry by following a few simple rules:

- Wear the jewelry carefully, because the layer of coating is very thin;

- Avoid high humidity conditions and potential contact with chemicals;

- Store in a protected location and wipe periodically with a soft cloth.

Rodinated items are not solderable, and to change the size of the ring, you will have to remove the layer of metal.

In addition to this, the disadvantage is that it is impossible to tell by eye what kind of metal is in front of us. In traditional gold processing, an experienced jeweler or even a seasoned amateur can tell by looking at the grade and quality.

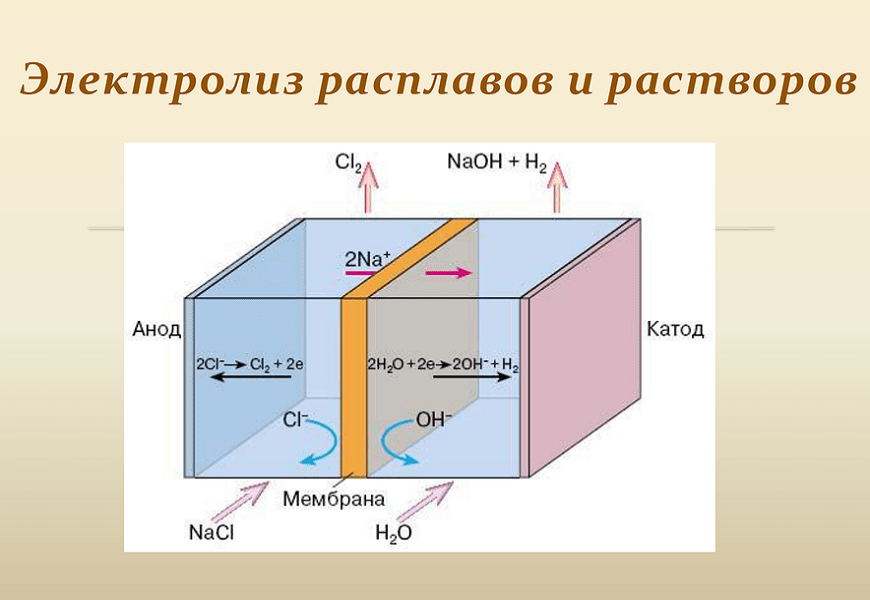

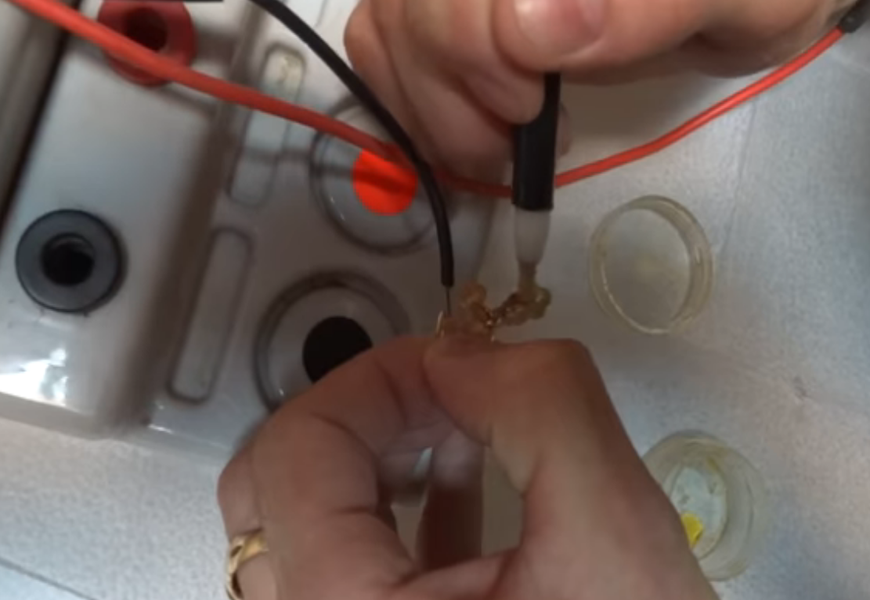

Rhodium-plating technology using electrolysis

The most common method of rhodium-plating jewelry is galvanic, or electrolytic. This is a physicochemical process that uses the principle of concentration on the electrodes of substances in a certain solution. The process is carried out under the influence of an electric current.

The technology involves several steps.

Step 1: Degreasing and rinsing in different solutions

The preparatory stage comes down to bringing the jewelry to the most suitable condition for electroplating, which is the coating of metal with a layer of another metal.

At this point:

- The jewelry is cleaned. Special solutions can be used for this purpose.

- Perform degreasing with alkaline solutions.

- Rinse several times with hot, then cold water.

- Soak for a short time, just a few seconds, in hydrochloric acid to enhance the adhesive qualities of the precious metal.

Adhesion is the property of heterogeneous substances by means of intermolecular interaction to stick to each other.

The particles penetrate each other, bonding the materials together. This is called surface activation.

By performing these preparatory procedures, you can be sure of the continued success of the plating process.

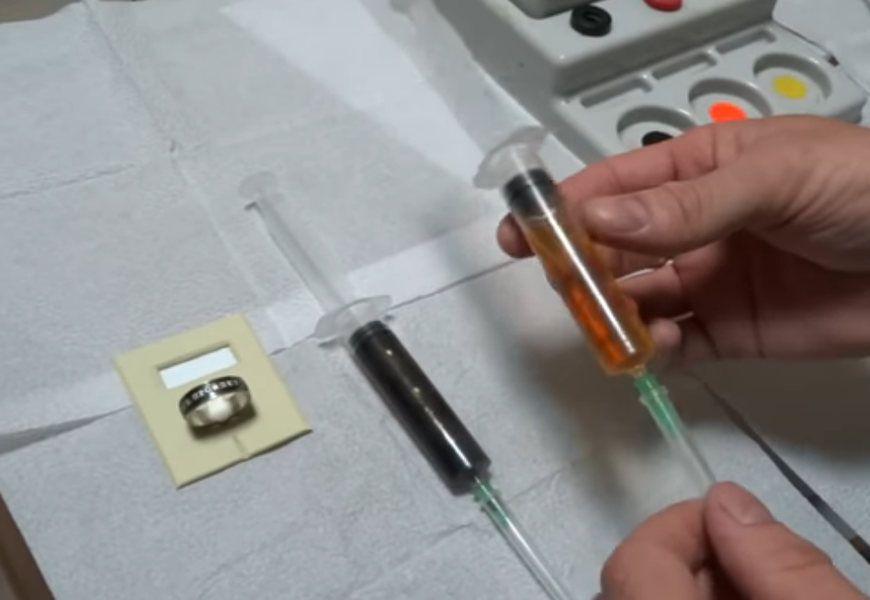

Step 2: Preparing the liquid rhodium salt solution

The rhodium electrolyte is prepared from salts of this metal. Rhodium ions are dispersed in the plating solution. Rhodium sulfate or rhodium chloride is used.

Step 3: Exposure to electric current through liquid

The galvanic method of operation is activated, which is the passage of a constant electric current of 2.5-3V through a prepared electrolyte. The gold product acts as a cathode, to which the rhodium particles move from the anode and are deposited on it in an even layer. This usually lasts from 30 seconds to 1 minute.

After electroplating, the jewelry is dipped into a container with water or under a stream of water.

As the process progresses, the thickness of the coating is monitored. The layer thickness used is 0.75-1.0 µm for rings, 0.1-0.5 µm for earrings and pendants

If the layer is very thin, it will be prone to abrasion. If it is too thick, there is a possibility of cracking.

Nuances of rhodium treatment of colored gold

Colored gold in jewelry refers to any kind of noble metal that differs significantly from pure gold. This is determined by the impurities that are added to the alloys gold. 100% gold is defined as 24-karat, divided schematically into 24 parts.

Additions of copper, silver, nickel, palladium and other metals change the color of gold toward reddish hues, yellow, green or white.

Red Goldoften used in the work of the 18-karat, contains 75% gold, 25% copper. Pink -18-carat: 75% gold, 22.5% (20%) copper, 2.75% (5%)silver. There is yellow, green, purple, blue, black gold. Black - one of the species directly related to rhodium, although there are others technologies of obtaining a precious metal of this unusual color.

When working with colored gold, which is most often red and yellow noble metal of standard samples, rhodium plating is not applied over the entire surface, but in places where the design elements are located. Most often, precious and semi-precious stones are used. The bed, where they are placed, is subjected to treatment.

Important: White gold, which has a characteristic yellowish hue, turns a perfect white color after rhodium plating.

Rhodium Colors

The original color of rhodium is silvery white with a faint luster. Specialists call this color bluish-white. The compounds are most often dark red. shadesThe Greek name of the city was given to it in the ancient Greek language.

But there are compounds of the oxide series, which are characterized by variations in gray color, they go up to black.

These elements are used to produce black gold by electroplating a black rhodium layer.

What are the similarities with gilding

Rhodium plating is similar to gilding when the electroplating method is used. The method of electroplating and immersion gilding is also available, but they are less frequently used in jewelry production or are not used at all.

Gilding The gold is applied, as a rule, to silver or non-precious metals. This is how inexpensive items with gold luster are made. Rhodium is not used for them, because rhodium is an expensive metal. At the beginning of 2021, its price exceeded the price of gold by more than ten times.

Types of rhodium plating

The main methods of making rhodium-plated gold: immersion and selective.

Items are immersed in a solution of rhodium salts, and then they are coated with the film as a whole. A part of the jewelry, such as the bed underneath the gemstones, is treated - this is a selective method.

Along with this, we can talk about the use of different solutions that provide two types of rhodium treatment:

- Normal, white rhodium plated.

- Black rhodium plating.

Conventional rhodium plating for a cool shine and a silvery hue

The usual rhodium treatment produces a silvery white color with a slightly cooler shade.

Black rhodium plating and antique look

Black rhodium plating can be applied to the entire piece of jewelry as well as to individual parts of the surface. If the jewelry has a complex shape, the black rhodium plating electrolysis It doesn't precipitate evenly. That is why it begins to resemble antique rings, rings, and earrings. This is especially true for items with dark or black stones.

Rhodium plating of gold jewelry. Regular care of rhodium-plated jewelry

Caring for rhodium-plated gold involves following simple rules

- Store items in a special box or case.

- Clean and polish products with soft cloths and brushes.

- Protect them from contact with humid environments and from contact with chemical reagents.

- Wear jewelry during the day, taking it off at night and before applying cosmetics.

- When the rhodium layer wears off, you can take it to a workshop to have it renewed.

There is a concept of technical maintenance of rhodium-plated jewelry. It means a periodic inspection of the product by a regular jeweler in St. Petersburg and other major cities.

If necessary, he will re-coat the gold with rhodium while the layer is still too thin.

How long does rhodium last on a piece of jewelry?

The thinnest coating has its own lifespan. It is related to the conditions in which the item is worn and stored. The gold hallmark has a certain influence on the longevity of the layer, which is shorter for non-ferrous metals.

As a rule, it is necessary to renew the coating of chains and pendants once in a year or a year and a half, it depends on the thickness of the layer. Rings keep the layer up to 3 years, and earrings and brooches keep it up to 7-10 years.

Average cost of rhodium plating

Rhodium is a valuable precious metal: on the market today, it is more than ten times more expensive than gold. The following figures are quoted: the re-plating of a white gold ring costs up to several thousand rubles, while the first rhodium-plating is cheaper than the following ones - a few hundred rubles.

The cost varies depending on the area covered or the weight of the jewel. It can be influenced by a factor of urgency.

What else does gold cover

In addition to rhodium plating, jewelry can be electroplated with a number of other metal elements: palladium, ruthenium, platinum.

An important property of these metals is the ability to increase the strength, resistance and wear resistance of the original product.

Video: rhodium-plating jewelry. Rhodium plating production cycle

Subject: Q&A

Doesn't rhodium plating make gold cheaper?

How much does it cost to give birth in Moscow very urgently?

Re-coating a white gold ring in Moscow or Chelyabinsk costs up to several thousand rubles. The cost varies depending on the area to be plated or the weight of the jewelry. If rhodium-plating is needed urgently, it also affects the price.

How often should I repeat the rhodium-plating procedure?

Why is white gold plated with rhodium?

What does rhodium plating on gold mean and how does it affect quality?

Gold is coated with rhodium for aesthetic reasons, but also to give special properties to the product. Rhodium is deposited on gold for aesthetic reasons and also to enhance the products' resistance to wear, moisture and weathering. The surface of rhodium-coated jewelry becomes stronger and less prone to deformation, scratches or cracks.