Galvanic metal silvering - is a way to give an object the aesthetic and functional properties of silver. Such a coating has a dense structure and gives the object new characteristics.

Metal silvering can be done in several ways waysEach of which is applicable in the home environment.

What metals are coated with silver. When metal silvering is necessary

Silver plating is required in those cases where the product must be given the properties of the precious metal of the highest grade.

Usually copper, aluminum, steel, and brass are subjected to the silvering process. It is obligatory to silver cutlery made of melchior, nesilber, and monel, because these alloys can oxidize in contact with foodstuffs.

Silver-plating light-colored metals is easiest. To give dark materials the properties and color of a pure precious metal, it is necessary to spray about 15 microns thick.

Metal silvering is suitable for the following elements:

- Titanium. BT-1 alloy is usually coated, other materials are difficult to process;

- Steel. It is possible to coat the material in silver, but an additional nickel or copper coating will probably be required;

- Bronze. The material easily "binds" with silver molecules, which allows you to quickly apply a protective coating;

- Brass. When working with this alloy, it is not necessary to apply an additional protective layer;

- Melchior or nesilver. The treatment is necessary for the daily use of the material because it allows it to become hypoallergenic;

- Copper. The material has a similar hardness to silver. The coating will improve electrical conductivity;

- Precious Metals. Silver, gold, platinum are some of the most preferred elements for electroplating;

Interestingly, it is not only metals that are coated with silver. For example, the substance silvermedine is used to form a protective coating on plants.

What is electroplating. The advantages of silver plating

Electroplating is an electrochemical method of treating objects by applying a thin surface film of another material to their exterior. Silver plating is called galvanic silver plating.

Method of application silver plating became known to mankind later than the method of applying gold. Originally, the moon metal, like gold, was used in combination with mercury, but this the way is different pronounced toxicity. The first patents for the technology were obtained in 1840, this laid the foundation for the electroplating industry.

Most often the technology is used to improve the aesthetic and performance characteristics of an object. It is also used to recreate exact analogues of things, an offshoot of the process called electroforming.

In industry, electroplating is used for the treatment of ferrous metals. This helps to achieve chemical inertness, so that the material can come into contact with water, dry gas atmospheres without harm.

The galvanic technique involves the use of an electrolyte. The electrolytic solution must be chosen based on knowledge of the properties and characteristics of the material to be treated.

The galvanic process is the immersion of the product in a solution of salts and acids, acting as electrolytes, with the further formation of a protective coating.

Important!

The structure of the coating will depend on the density of the electricity. It is defined as the ratio of the strength of the electricity to the size of the surface of the material.

The silvering process offers the following advantages:

High coating hardness

Lunar metal has a high hardness - up to 90 kg/mm2. Silver plating promotes an increase in the resource of wear resistance, extending the life of the object.

Good electrical conductivity and thermal conductivity

Silver has the highest electrical conductivity and thermal conductivity at room temperature of any metal in existence. That is why it is used to coat electronic devices.

Anticorrosive properties

The anti-corrosive properties of silver protect the silvered material from destruction due to chemical or electrochemical reactions with the environment.

The use of electroplating makes it possible to turn iron and its alloys into stainless materials.

Inertness to many substances

Silver, like all noble elements, is an inert material and in nature practically does not interact with other substances. It is odorless and forms no toxic compounds.

It is worth bearing in mind that the lunar metal is sensitive to hydrogen sulfide. Even minimal amounts of hydrogen sulfide can lead to the formation of silver sulfide on the surface.

Reflective properties

The metal is capable of reflecting up to 95% rays. This property is useful both in industry, such as in the production of submarine parts or glass for mirrors, and in the home.

Giving a decorative sheen

With galvanic silvering, you can achieve an attractive shine, even if the object is made of dark materials.

In addition to these characteristics, the protective coating gives the object antibacterial qualities. Lunar metal ions have antiviral, bactericidal, and disinfectant properties.

Galvanic silvering at home quickly, easily and efficiently. Step by step instruction

Galvanic silvering in at home can be performed in several ways that do not require expensive chemicals.

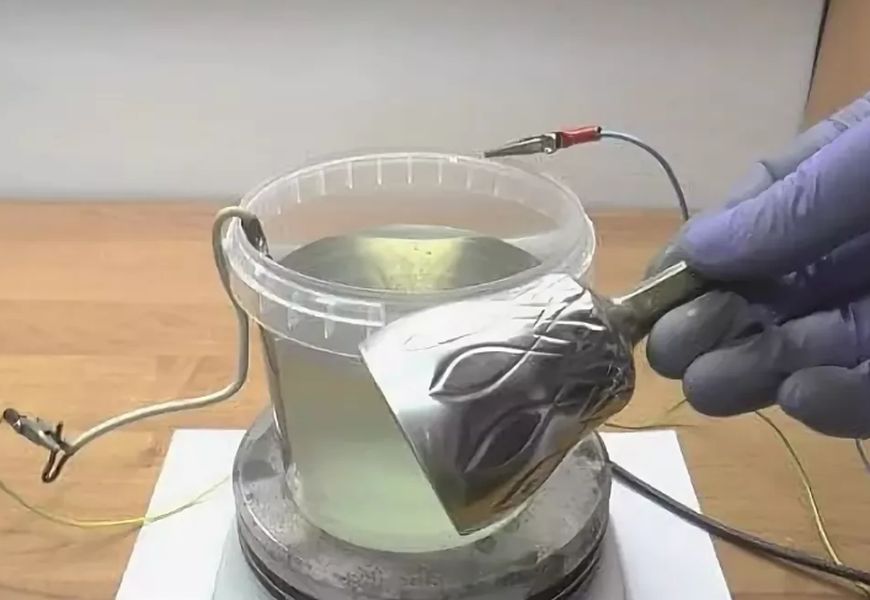

The galvanic method requires you to connect the item to be treated to the cathode and the silver item to the anode. Under electrical action, silver molecules will begin to collect in the electrolyte on the item to be treated and become a protective coating.

Let's look at the galvanization process step by step.

Prepare the necessary tools

The process will require:

- A plastic or glass dielectric container of suitable size;

- Electrolyte;

- Silver;

- DC power supply;

- Holder for fixation;

Также рекомендуется приобрести ювелирные весы, поскольку отмерять реактивы потребуется с точностью до грамма. Дешево приобрести необходимое оборудование через Интернет, в точках авто- и стройматериалов.

Prepare solutions and chemical reagents

The composition of the solution depends on the alloy of the object to be treated. Silvering copper is possible with the following essence:

- Silver chloride - 10 grams;

- Sodium carbonate - 45 grams;

- Potassium cyanide - 45 grams;

- Sodium chloride - 20 grams;

- Aqueous ammonium hydroxide solution - 80 ml;

There are several types of silvering electrolytes, among them:

Sodium bicarbonate electrolyte with soda

The cyanide electrolyte for silvering contains:

- Silver chloride - about 20 grams per sheet of mixture;

- Potassium hexacyanoferrate - about 20 grams per liter;

- Calcined soda - about 30 grams per liter;

The electrolyte will be characterized by a reaction at low current concentration and room temperature.

Electrolyte of bicarbonate with potash

This electrolyte can be heated up to 750 оC, and the cathodic concentration of electricity to 2 a/dm2.

Composition per liter:

- Silver chloride - about 40 grams;

- Yellow blood salt - about 250 grams;

- Potash - 10-25 grams;

Potassium iodide electrolyte

This electrolyte requires an electric voltage of 0.10 to 0.30 a/dm for silvering2The temperature is standard room temperature.

Composition per liter:

- Sulfuric acid precious metal - about 35 grams;

- Potassium iodide - 650 grams;

- Ammonia solution - 80 ml;

- Potassium pyrophosphate - 45 grams;

Connecting the vessel to the current source

Electrolysis is the decomposition of a substance into its constituent parts by passing an electric current through its solution. This physical and chemical process is the basis for the following steps.

Once the electrolyte is prepared and filtered, it must be poured into a galvanic vessel. The next step is to connect it to the electric current.

Important!

The area of the positive electrode should be at least twice as large as the negative electrode.

Product immersion

The material to be treated, acting as the negative electrode, must not come into contact with the vessel and the positive electrode.

The process temperature and current density need to be controlled. It is desirable to keep the voltage in the range of 12-24 W.

Cleaning and polishing the result

Post-treatment polishing is almost never used because it can remove a significant layer of applied metal. For getting It is recommended that the smooth surface be polished and cleansing tentative.

After silvering, it is sufficient to rinse the material under running water.

The electrolysis method is suitable for both plating and silvering removal. In the second case, the anode will be the contaminated precious metal and the cathode will be the stainless steel strips.

Nuances of galvanic silvering

Galvanizing with your own hands is a rather complicated procedure. To achieve a positive result, it is necessary to take into account the properties of the processed material, to observe safety precautions, to perform the process in accordance with a strict sequence.

It is worth bearing in mind that galvanic silvering on its own cannot seriously strengthen the strength of the alloy, the result is aimed rather at performing a decorative function. To get an impressive protective layer, the procedure should be performed about 10 times in a row.

The thickness of the coating in a single procedure is thinner than a human hair (about 20 millionths of a meter).

It is better to clean and degrease the surface to be treated

The object can be degreased with alcohol or sandblasted beforehand. Sanding with special pastes or sandpaper is also suitable.

An organic solvent can be used to remove the greasy film. If the material of the product is cast iron or steel, essence containing silicate glue, soda, caustic alkali are used for cleaning.

Dark metal will require a thicker layer of silver

Light surfaces are much easier to silver. To prevent the darker shade of the base material from showing through the spraying, the thickness of the layer to be applied should be several times greater.

Consequently, darker materials are more expensive.

It is dangerous to use cyanide electrolytes for silvering at home

A huge drawback of cyanide electrolytes is their toxicity. This is due to the interaction of free cyanide with carbon dioxide from the air.

Work with this electrolyte should be done indoors with good ventilation or outdoors, since ingestion of hydrogen cyanide can be fatal.

Silvering of brass, copper, and other metals has only one drawback - the layer of precious metal rubs off over time, but it can be restored by repeating the electroplating procedure.

Alternative ways of silvering metals

Metal silvering at home is possible in a number of ways alternative ways. They will require special reagents, as well as the observance of safety precautions.

Other methods of silver treatment include:

Surface chemical treatment

The technology involves the use of chemicals that bind with the material to be treated to form silver microparticles.

The basis of the chemical treatment is anti-chlorine, a special reagent used in the photography industry. Also required:

- Formalin - about 10 drops;

- Ammonia - about 10 drops;

- Sodium thiosulfate - 1 liter;

The processing itself is as follows:

- Formalin and ammonia are added to the antichlorine.

- Clean the surface of the metal item, then dip it into a boiling soda solution. Afterwards, rinse with running water.

- The product should be immersed inside the container with antichlorine and left for 2.5 hours.

- After removing the object, it should be washed and dried.

Dive technology

How can metal be silvered using the immersion process? In this method, the item to be treated is immersed in a silvering essence, which consists of certain substances. The composition depends on the alloy of the product.

Let's consider a technology reminiscent of galvanizing. For its implementation, the composition of the essence will be as follows:

- Water - 100 ml;

- Carbon silver salt - 10 grams;

- Sulfuric sodium salt - 100 grams;

The product is immersed in the resulting liquid together with the zinc part, which should touch its surface.

Silvering with special pastes

The cost of the silvering paste is from 1000 rubles. You can buy it in specialty stores or order it online at the site "Ozon".

The paste is not difficult to make at home. For this you will need:

- Silver chloride - 7 grams. Formula: AgCl.

- Sodium chloride - 9 grams. Formula: NaCl.

- Potassium tartrate - 9 grams. Formula: KC4H5O6.

- Chemically precipitated chalk - 6 grams. Formula: CaCO3.

In dry form, the components are thoroughly mixed, then they must be ground in a mortar. The components are able to retain their properties for quite a long time if you store them inside a darkened container.

Before starting the process, the resulting powder is diluted with running water to a paste. The resulting mass should be rubbed onto the item until it has a silver luster.

You can use leather or other soft material to apply the paste.

Silver plating by heating the metal

To prepare a special solution, you will need:

- Silver chloride - 30 grams. It can be obtained from the nitrate of the precious metal;

- A little bit of baking salt;

- Water;

- Potassium hydrotartate - 160 grams;

2.5 tablespoons of the compound should be added to 5 liters of water, which must then be boiled.

It is not recommended to use an open fire for heating, because it is more difficult to control the temperature. An electric stove is best for this purpose.

The material placed in a clay sieve should be lowered into the boiling solution. The liquid should be stirred with a stick made of glass or wood without stopping.

Question and answer section

Silvering with your own hands using an anode and cathode, what is it?

Silver plating, what is the state standard?

The coating itself is usually made up of pure 999 precious metal. Silvered copper will be branded as copper alloy, with the plating thickness in microns, e.g. 0.1.

Silver plating price?

The average price of silver plating - from 250 rubles per 1 dm2.

Table: cost of professional silver plating

Specialized companies offer electroplating at an affordable price and in the shortest possible time. Professionals help you choose the thickness, prepare the surface, and perform the final treatment.

Contacting specialists will help save health, money and personal time.

The table below shows the average plating prices for jewelry, current as of 2021:

| Service | Cost | Minimum order price | The service includes |

|---|---|---|---|

| Full coverage | 100 rubles per gram | From 1200 rubles | Cleaning, polishing the product |

| Partial plating with electroplating pencil | 250 rubles per 1 cm2 | From 300 rubles | Cleaning, polishing the product |

| Coverage restoration | 150 rubles per 1 cm2 | From 300 rubles | Cleaning, polishing the product |

For an additional cost, you can order the polishing of the jewelry, which allows you to get rid of severe dents and scratches.

Safety precautions

Chemical silvering must be performed with proper precautions.

- For work you will need: closed-type glasses, rubber gloves, rubberized apron, respirator.

- The process is only possible with good ventilation or outdoors.

- The reagents must be stored separately from each other.

- Remove silver-plated objects from electroplating baths only after the electric voltage has been removed.

- Waste must be disposed of safely.

Video: silver plating method

Jeweler's comment