Gilding is used in jewelry for quite a long time. Gilding itself is the process of applying a decorative layer to various items. There are different types of gilding with their own characteristics.

What is gilding and gilding. History of the art of gilding - a hot way from antiquity

Gilding is a subtle gold layerThe thickness varies from 1 to 25 microns, which is used to coat a variety of surfaces to give an object a resemblance to the precious metal. The thickness varies from 1 to 25 microns.

The technology allows the use of gilding in jewelry design, interior design, architecture, cosmetology and the food industry.

The art of gilding has been known for many thousands of years. Previously, two methods were used: cold and hot. The cold method was based on attaching gold plates to the surface. The hot method involved the use of fire: gold and mercury were applied to objects. The surface was burned, the mercury evaporated and the gold adhered firmly to the base. Knowledge of the toxic effects and severe poisoning of workers in the workplace forced the method to be abandoned.

The first gilded costume jewelry and household items were discovered back in ancient times. The ancient Egyptians were among the first to cover the sarcophagi of the pharaohs with gilding. Then gilding was mastered by China and ancient Russia. Since then, there have been many techniques on how to coat different objects with gold.

The electroplating technique of gilding has been known since the 19th century and is considered safe for use by jewelers. Electroplating was a new stage of development in the gilding era.

The active study of the properties of gold made it possible to use gilding techniques in painting, icon painting, forging or casting to decorate furniture, and building architecture from the decoration of ancient Egyptian tombs to the pompous Baroque style of Bartolomeo Rastrelli.

The main characteristics of gilding

Jewelry gold plating has a number of valuable properties that define its main functions:

- ennoble the appearance of an inexpensive product;

- protect surfaces from corrosion and oxidation.

Properties in turn depend on the thickness of the layer of gilding, precious metal.

Spray color: yellow to pink

The gilding of the metal is done in different shades, thanks to the addition of impurities. The white color is the result of mixing gold and silver elements. A pink hue is obtained by adding copper.

It is important to remember that the original color of the precious metal depends on the original grade of gold.

Quality and application technique

The quality of the gilding depends on the application technique chosen. Different methods of application, special reagents, and professional substances can be used. Often when gilding different surfaces, a layer can be used to help even out the color and increase the hardness of the material.

Layer thickness and durability

The longevity of objects largely depends on the thickness of the gold layer. To keep the gilding for longer, a layer of at least 0.1 mm thickness is applied. In this way, it is possible to keep the luster of items for several months with proper care.

Jewelry gold plating is divided into types according to thickness:

- standard: 385 sample, not more than 2.5 microns;

- TOP gilding: 585 hallmark, does not exceed 2.5 microns.

- white gilding: white shade, 2.5 to 5 microns.

- rose gilding: any assay, pink tint, layer - at least 2.5 microns.

Where gilding is used, in what areas

Nowadays gold plating is used in many fields:

- automotive industry;

- jewelry making;

- art, painting;

- interior decoration;

- dentistry, medicine;

- electronics;

- beauty industry;

- food industry.

What metals can be gold plated

Jewelers quite often use gold plating for silver objects. Gold plating is also available for bronze, copper, cast iron, brass, aluminum, galvanized iron, and other known metals. Certain industries practice the gilding of wooden, clay, plastic and plaster objects. A gold layer can be given to ceramics and cardboard.

Gold Coloring Techniques

The technique of gilding changed, improved and divided into two main methods of application: clay and on mordant glue.

- Antique clay gilding: multi-layer surface preparation with the use of a complexly composed primer, polyment for the application of gold leaf itself for relief. This method is suitable for the treatment of wooden coatings indoors, clay-based products, and icons. Today there are special mixtures, ready to use, which are easy to buy in St. Petersburg, Moscow and other regions of the country.

- The popular gilding on glue: a gold layer is applied to a special oil varnish-mordant. Advantages of the method: simplicity, accessibility, resistance to moisture. This technique is used by craftsmen more often and on different surfaces: metal, wood, plaster, mastic, stone.

Other types of gilding based on the above:

- Combined with the use of a gelatin-based adhesive solution under the mosaic

- Gilding with created gold using bronze powder in the same color as the gold.

- Bronzing the product with bronze powder powder.

- Water-synthetic gilding so it doesn't take a long time to prime.

- Garlic the old-fashioned way with garlic juice and golden plates.

Types of gilding by a specialist

Several simple, accessible methods of gilding are actively used. Gold leaf or gilding can be used to cover interior elements, household items, and costume jewelry.

Susal to cover

The gold leaf method involves the use of 960-gold leaf. The method is used to cover the domes of temples, icons, sculptures, fountains, clocks and other parts of decoration. Recently, the use of food-grade gold has become popular, for decorating cakes, desserts, candies, and even meat dishes.

For such purposes, a wisp with a plate thickness 10 times thinner than the cross-section of human hair is used.

Inexpensive use of tattoos

Potash is now considered a cheaper alternative to gold plates. Due to the absence of precious metals, a gram of such Covers Costs dozens of times less. It is produced in the form of gold foil or strips. It is a copper-aluminum or zinc alloy.

By changing the alloy composition it is possible to imitate gold, silver, bronze material. It is possible to apply a pattern to such surfaces.

Rhodium can protect jewelry from damage.

Gilding with your own hands

The gilding in at home provides for several ways:

- treatment of objects using chlorine gold;

- zinc contact;

- processing galvanic ways.

These methods can be used at home, but will require chemicals, tools and special equipment, which is not available to everyone.

Recipe for dyeing with gold chloride

For gold plating at home, chlorine gold is used, which can be made by by melting the precious metal in a "hellish mixture" consisting of a 1:3 proportion of nitric and hydrochloric acids.

After placing the metal in the solution, the liquid should be evaporated. It is important that the fire is separated from the container in the process. As a result, a dry mass of chloride gold remains at the bottom.

Important: Vaporize acids very carefully so as not to burn your hands or mucous membranes of the respiratory system.

Immediately prior to use, the mass is mixed with potassium cyanide and the resulting gold until a mass with the consistency of mush is obtained. The prepared mixture is used to stain objects. When finished, allow the material to dry, rinse the surface, then proceed to polishing.

If you add ether during the gilding process, it will allow you to decorate the applied layer of gold with a pattern, make an inscription or a binding. When finished, wait for the ether to evaporate and give a shine by polishing the surface with a cloth.

Contact zinc

To obtain a thick layer, gilding at home is done with zinc contact. To prepare the composition for coating silver items will be required:

- water - 1 liter;

- gold chloride - 8 g;

- table salt - 33 g;

- salt of potassium carbonate - 33 g;

- yellow blood salt - 33 g.

Gild copper and brass with the following mixture:

- water - 1 liter;

- gold chloride - 2 g;

- potassium caustic - 3 g;

- phosphorus sodium salt - 5 g;

- potassium cyanide - 16 g.

Before applying the solution, the surface should be well cleaned of dirt. The object is placed in a preheated gilding mass. The last thing to be added is a zinc stick, which is a binder.

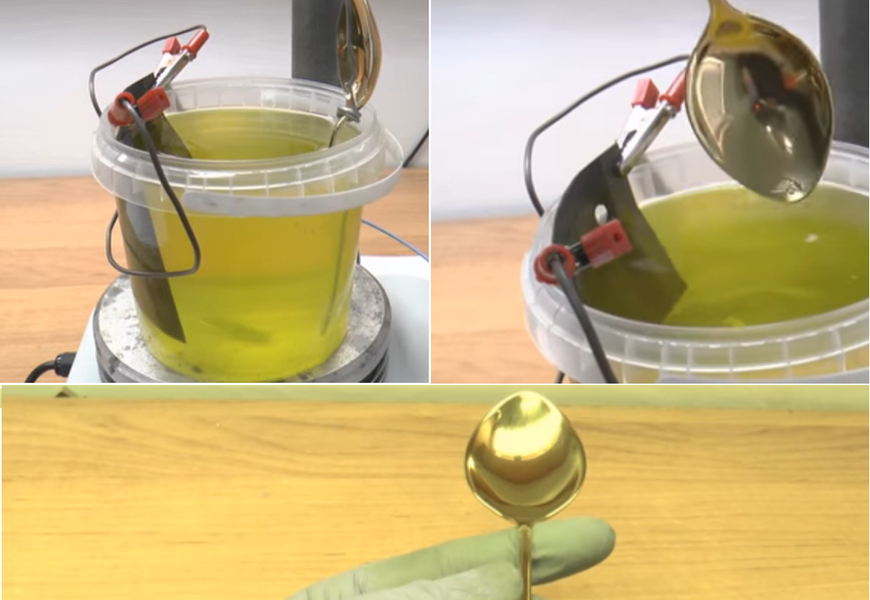

Electroplating with the use of electric discharge

The electrolytic method of electrolytic gilding provides a strong and high-quality coating. The hue of the coating obtained by this technique will directly depend on the constituents of the gold mass, can range from reddish to light yellow.

The technology provides for two types of compositions:

- Electrolytes of the first type.

Preparation of mixtures:

- sodium phosphate (60 g) + water (700 ml).

- Chlorine gold (2.5 g) + water (150 ml).

- Potassium cyanide (1 g), sodium bicarbonate (10 g) + water (150 ml).

Carefully mix together the liquid with sodium phosphate and gold chloride. Lastly add the solution from step 3. The liquid is heated to 62° C using a platinum anode.

- Zelmi Gold Bath: electrolytes of the second type.

It is used to cover silver, steel, tin, copper, brass, other metals.

The preparation of the electrolysis consists in the sequential preparation:

- Potassium iron blue (1 g) + sodium carbonate in crystals (1 g) + water (30 ml): Bring to a boil, using porcelain containers.

- After boiling, rattlesnake gold, precipitated by ammonia, is added and boiled for another 12 minutes.

- Then with the formation of a precipitate, the solution can be filtered. A liquid resembling liquid gold is obtained.

The product is immersed in the solution for 16 hours, after which it acquires an interesting matte color.

Matte effect

Lacquer, olive oil and pinena in a mixture called gulfarba, which is used to treat the surface. One day after application, gold leaf is applied on top. The solvent-based mixture allows you to give the gold a matte finish.

Popular uses for gilding

Gilding has been used for centuries in many different applications. Its most popular use is in modern technology in jewelry and food production.

Quality gilding of modern jewelry

In their jewelry, gilding is used by famous jewelry brands such as:

- SOKOLOV. Most of the products are made of silver. High-grade gold is used for their coating. The thickness of the layer can be up to 5 microns. The palladium serves as a "layer" between the layers. Such coating not only improves the appearance of the jewelry, but also enhances its durability.

- Pandora - manufactures jewelry made of noble metals. In its technology it can use gold plating for a special line of jewelry. Pandora Shine line of silver items using electroplating. This method allows you to give a golden hue, smoothing the surface. Pandora Rose series is distinguished by an interesting pinkish tone of products. The jewelry is made of silver, copper, palladium and 14 carat gold. rose gold. The pink layer protects the surface from tarnishing and enhances durability.

Turkish gold offered to tourists is also popular. Turkish craftsmen use alloys of gold, copper and silver. Gilding is used to enhance the appearance. Regardless of the amount of noble metal composition, jewelry is considered jewelry, with a corresponding value.

Susal in the food industry

As far back as the Middle Ages, it became popular to use gold as a food additive; it was attributed medicinal properties. This trend has been revived these days. Gold leaf can be found in pastry shops and restaurants. Desserts, pastries and candies are covered with it. Individual gourmets prefer gilding with seafood and meat. For convenience, the food industry uses gold in sheets, powder, flakes and granules.

Such decoration is considered an important accent of the dish, emphasizing the festive atmosphere.

Branding and marking of gilding in Russia

Any piece of jewelry, even gilded ones, must be hallmarked. In Russia, it is customary for gilding to indicate the metal that has been gilded, so it is more often stamped 925 Sample from silver. Imported gold-plated items are always indicated by the carat index. The carat and letter symbol indicate the method of gold plating.

Gilding markings abroad:

- Vermeil - 333-999 proof (8-24k);

- KHGE - 585 or 750 proof (14 or 18k);

- KGE - 750 (18k);

- Clad in Gold - 750 (18k);

- EP - 750 (18k);

- GEP - 750 (18k);

- Cold Layered - 750 (18k);

- COLD PLTED -750 (18k);

- KARATCLAD - 750 (18k);

- KGP - 750 (18k);

- Layered - 750 (18k);

- Overlay - 750 (18k);

- Technibond - 750 (18k);

- WGP - 750 (18k);

- YGP - 750 (18k);

- Plaque - 750 (18k);

- Gold Clad - 750-999 (18-24k);

- KGB, KTGP - 999 (24k).

Pros and cons of gilding

For many centuries, gold jewelry was an indicator of wealth, power, status of the nobility. Gold plating was applied to everyday objects, dishes. The material was used to decorate furniture, buildings outside and inside. On this basis, the advantages are highlighted:

- acceptable price of the product;

- dishes and other products look as luxurious as possible;

- the golden layer can be restored.

Disadvantages of gilding:

- the coating is short-lived;

- The gilding is gradually wearing off;

- the lifetime of the coated object is influenced by the layer, gilding grade.

Top - 6 tips to distinguish fakes from gold

About half of all gold items are high-quality imitations, which can be bought at the price of the precious metal even from trusted dealers. That means it is important to know how to check for authenticity before buying. Signs of counterfeiting are considered:

- Uneven layer of gilding. Most often, the material is poorly adhered or partially rubbed off during shipping.

- Check with a magnet. Real precious metal is not attracted by a magnet. But the method is not quite effective, because the magnetic field ignores most metals.

- Defects in the area of the branding. When making a forgery, the branding is transferred from the original to the copy. If you examine this area well, you can find defects, which will be a sign of gilding.

- Chemical exposure to reagents. If you often buy gold from different sellers, it is worth buying a set of special reagents that can be used to easily identify a copy.

- Alcohol to the rescue. After rubbing alcohol, the gilded item will darken.

- The Vandalism Method. By making a small scratch on the surface, it is easy to detect a fake. The gilding will be crumbled by the smallest particles, the damage will stand out.

It is important to remember that the only reliable method of verification is inspection of the product by a specialist. But you can use it only after purchase.

Rules of gilding care: wearing, storage, cleaning

Of course, the gilded layer will not last forever, but you can extend its life with proper care and cleaning of the surface. It is important to observe the following rules:

- Store gold-plated items separately from other items;

- It is better to remove jewelry before the pool, shower and gym: limit contact with moisture and water;

- To clean up The decorations are wiped with alcohol using absorbent cotton disks;

- To prevent gilding, it is sufficient to wipe regularly with a dry piece of suede cloth;

- It is recommended to show the product to a craftsman once a year, if necessary to restore the coating.

Video: Gilding from A to Z. Beautiful jewelry and an alternative to gold

Question and answer section

Does the gilding darken or not?

How do I coat metals in gold at home?

- immersion in a chemical compound with zinc contact;

- the use of electric discharge in the solution;

- staining with chlorine gold.

Is it possible to gild the metal yourself without gold?

Jeweler's opinion and feedback