It happens that a gold item can no longer be worn: an earring is missing or a ring is broken or cracked. Most often, such jewelry is sold or put in a pawnshop. What happens to it afterwards? They are melted down and new items are made. There is such a process as refining gold. Let's talk about it in more detail.

What gold refining in jewelry means

So, what is it gold refining? This is the name given to the process of cleaning metal. Not external cleaning, which is the process of returning a piece to its former purity and luster. Refining or affining is the removal of additional impurities from the gold. This process can also be referred to as refining. Refined gold, like sugar, is a perfectly purified item.

For example, when mining It is difficult to find perfectly pure gold bars. More often than not, they are grains mixed with other rocks or just earth. It is also important to know that precious metals, the same as gold and silver, are mined from the same ores. Therefore, they are always present in each other's impurities.

Precious metal mined It is processed at the plant, where it is refined.

The result is refined gold, a 999.9 metal.

Accordingly, used gold items also have additional impurities - other metals. That is why they need to be refined. For example, you can get 999 from a 585 piece of jewelry.

Raw materials for refining

To get refined gold, they work with certain raw materials. This is gold-containing materials:

- Natural mixtures containing precious metal. These can be minerals, rocks or even river sand.

- Scrap gold. Used gold items and elements. For example, jewelry scrap is earrings, rings, chains, bracelets, pendants, brooches. Technical - radio scrap, radio components, microcircuits. Household scrap - coins, crockery, watches, badges, medals. This can also include some types of edged weapons (sabers, swords, daggers), souvenir and antique items.

- Waste after cleaning a medical alloy. For example, gold plating applied by gilding.

- Concentrates of lead production. Lead contains the noble metals gold and silver. To separate them, zinc is used. When heated, it forms a silvery foam that takes the noble metals and separates from the lead.

- Waste gold. This type of raw material constitutes the largest share subjected to refining. This is all of the precious metal mined. It goes to processing plants, where it undergoes refining treatment.

As you can see, gold is not only a product of mining. The noble metal is present in everyone's life: in jewelry and household items.

Legal aspects of gold mining by refining

All transactions involving the circulation of precious metals, stones and pearls are legally controlled by the state. Illegal sales are classified as economic crimes, since they pose a threat to the country's economic security.

Places to clean metal

It is possible to refine gold under special conditions. Where does this procedure take place?

Industrial cleaning at plants by electrolysis

The refining of the precious metal is carried out by industrial companies that specialize in this process. Gold is refined by means of electrolysis. This process involves passing the raw material through an electric current, causing it to separate into pieces. Of these, it is easy to separate the noble metal. There are very few such enterprises. Russian enterprises: "Uralelectromed", "Krastsvetmet", Kolyma refinery, Novosibirsk refinery, "Tau-Ken Altyn" plant in Kazakhstan.

Equipped laboratories

If refining is carried out on a small scale, specially equipped laboratories are suitable.

Home Workshops

It is hard to imagine, but gold refining is possible at home. To carry out the process, you need certain materials, equipment, and knowledge of refining techniques.

Refining methods

There are two ways to purify a precious metal or to separate it from impurities:

- chemical;

- electrochemical.

The first method is associated with the interaction of substances, the second - with an electric current. Let us consider each of the refining methods.

Chemical methods

There are methods that are applicable in at home. But some . ways are only allowed in laboratories due to the increased danger. For example, the affinity is carried out by means of the strongest reagent hydrazine hydrate with the formula N2H4-H2O.

Let's list and examine how the simplest chemical affinity methods are carried out.

Dry cleaning by the Miller method

This method of refining precious metals is used only by industry, because the chlorine used in refining has a high level of toxicity and corrosiveness. The method itself: all of the raw material is crushed and chlorine gas is passed through it. All non-ferrous compounds combine with chlorine and evaporate. The metal sample is thereby increased. Of the pluses of Miller's method it is worth highlighting:

- low cost;

- use in rooms of small size;

- for a short time: just a few hours;

- efficiency: scrap can be used to produce 999 gold samples.

A crucible is needed to purify the raw material, which is a vessel that is fireproof. When gold-containing components start to melt, chlorine enters the crucible through a special tube, and then excess impurities are evaporated together with it, and the noble metal chloride appears on the surface. This method makes it possible to refine gold even from alloys consisting of complex components.

Wet method with royal vodka

The wet method allows you to refine gold from ligatures by dissolving with certain liquids. For example, one popular refining method is dissolving scrap gold with tsarist vodka.

For reference: Royal Vodka is a mixture of concentrated acids: nitric and hydrochloric. By the way, royal vodka is a rare substance that dissolves noble metal.

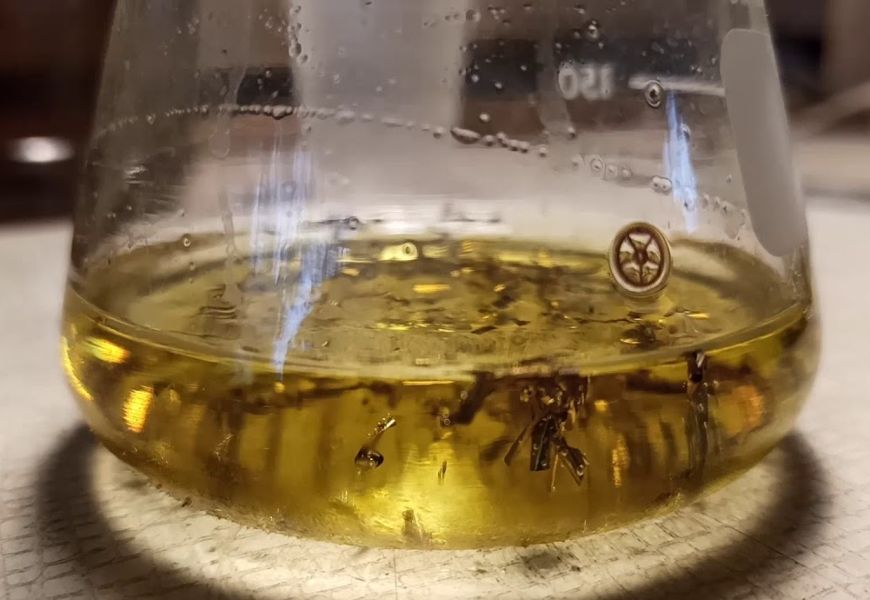

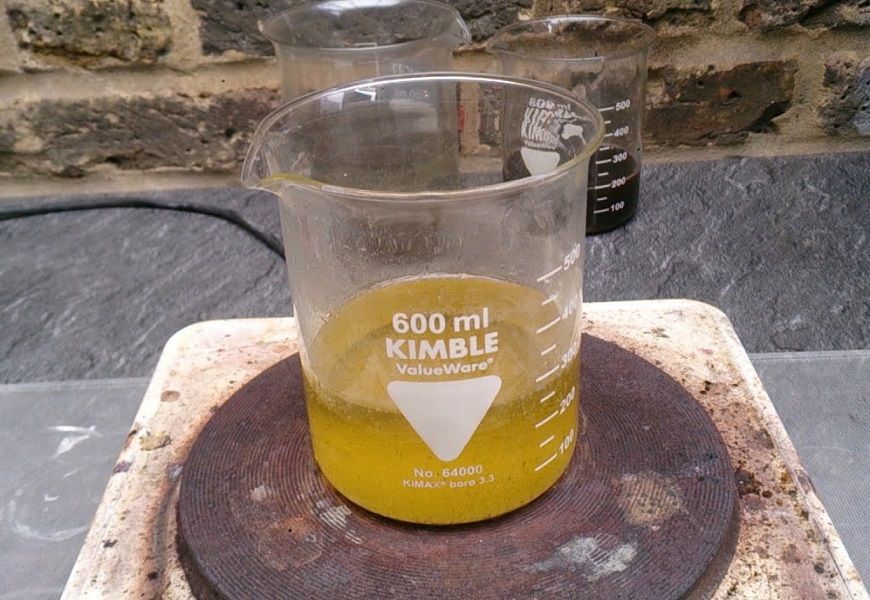

What does the refining process look like? Vodka is heated together with the metal and copper sulfate, which results in the precipitation of gold. If the process is done correctly, the output is pure 999th grade metal.

Another tool for wet refining: Lugol solution, a mixture of iodine and potassium.

Gold in liquid form, such as a solution, can be treated with tin chloride powder. The mixture is left in the container for about a day, after this period, the metal settles to the bottom. This method is convenient and safe because there are no toxic emissions.

Electrolytic method

Electrolysis - is a method by which raw material elements are isolated on electrodes. Refining is carried out in porcelain baths of up to 25 liters. The contents of the baths are heated in a water bath. When heated to 50-60 degrees, an electric current is passed through a solution of acid and gold chloride (electrolyte). Particles of the precious metal are deposited on the electrodes.

Electrolysis gold refining is very dangerous at home. It is only done in the laboratory.

How to refine microchips at home

Despite the complexity of the refining procedure, you can do it yourself at home. It is possible to refine both jewelry and household scrap, as well as technical scrap, such as microchips that people usually throw away. The main thing is to create the right conditions, correctly prepare the raw material and the necessary equipment.

Tools, materials and raw materials needed

What gold-containing parts can be used?

- KT 101, 103, 117, 603, 613 series transistors;

- microcircuits from old TVs, tape recorders, radios;

- Soviet-made connectors;

- Radio tubes containing not only gold, but also silver and platinum: up to 16 grams of the purest precious metal can be extracted from a single tube;

- semiconductors, diodes, light-emitting diodes, stabilizing diodes, thyristors, capacitors;

- Computer parts: connectors, chips in processors, a lot of precious metal in older models;

- coverage of Soviet-made metal wristwatches;

- SIM cards.

All this junk can lie around for years in the attic or at the cottage, and the owner will not even know how rich in gold it is.

What else is needed besides microchips?

- whiteness is normal;

- sodium bisulfate.

Or:

- whiteness;

- battery electrolyte;

- table salt.

By mixing these ingredients, it is possible to obtain chlorovate acid, which separates the precious metal from the components.

The procedure can also be done with iron sulfate. To do this, you need:

- sulfuric acid iron: it is obtained by dissolving vitriol in water, and rusty nails are also added;

- sodium chloride;

- hydrochloric acid.

You will also need porcelain melting pots, pouring pots, and wooden sticks for stirring.

Preparing for the procedure

Gold refining is carried out under the following conditions:

- open all the windows in the room to ventilate;

- microcircuits should be crushed, for example, with pliers, removing the plastic parts;

- the used solution is heated, gradually pouring in the acids;

- heat until a gray (whiteness) or brown (vitriol) precipitate appears;

- filter the solution;

- melt the resulting precipitate to produce gold colors.

The cooled gold should be rinsed under running clean water.

Basic security measures

Observance of safety rules is one of the basic rules in gold refining. In order for gold refining to proceed properly and safely, you need to use usable components. Gloves and face shields should be worn when working. No children should be around.

The mystery of refining

It is difficult for the average person to grasp complex terms like sulfite, pyrosulfite, or sodium metabilsulfite. All of these terms refer to the refining of gold with acids. But the process of obtaining the real precious metal is truly beautiful and unique. From a bubbling liquid, then from a gray or brown mass, a gold mass emerges, shiny and iridescent. This mass will later become the basis for some equally unique jewelry: earrings, bracelets, or pendants.

Alloying gold sludge into gold bullion

To refine at home, you will need the following equipment:

- The precious metal itself, which should be cleaned - jewelry or household scrap;

- two refractory crucibles in which the melting will take place;

- 999 copper;

- nitric acid in relation to the prepared gold 10/1;

- hydrochloric acid;

- Sodium tetraborate - it can be purchased at a drugstore;

- burner;

- To stir the melt you need a birch or aspen stick, you can also use a graphite pencil rod;

- tongs or tweezers for adding raw materials;

- gauze;

- crucible lid, so that the air goes out, it must have a lid on it;

- electric stove;

- fireproof glass flask;

- clean water.

Be sure to see that all prepared tools are intact, without cracks. Dirty equipment must not be used. Chemicals must have a current expiration date.

Step-by-step instructions on how to prepare for refining:

- Use the wire cutters to shred the scrap;

- crucibles should be dried and calcined so that they do not burst;

- start melting the gold, stirring constantly;

- gradually add pellets of copper with tweezers to the melting mass; you need to wait until the added pieces are melted, then add new ones;

- the resulting mass should be poured into a flask;

- Then pour in nitric acid little by little: you need to watch the reaction, pour it in as it subsides;

- wait for the contents of the flask to boil;

- then add clean water, stir, drain water;

- add borax, some pure water, wrap the gold in gauze and drop it into a clean crucible;

- When the mass is homogeneous and the gauze has decayed, continue to melt;

- sprinkle the gold with borax until it turns a rich yellow, shiny color;

- leave to cool.

The process of obtaining pure precious metal is very beautiful and mesmerizing.

Method for refining refined gold

After gold is solidified by ingot, place it in a solution of hydrochloric and nitric acids with water (proportions: 20/10/500 ml). After 5 minutes of boiling in hydrochloric acid, wash the refined metal with clean water, washing off the excess borax. Polish the metal with a soft cloth for luster. The refining process is finished.

When refining noble metal, it is important to observe safety rules. The procedure should be carried out only outdoors, away from residential areas. If you have a private house, then in the backyard, you can go to the country house. During the procedure itself, work with gloves, do not lean close to the crucible or flask, so that the released nitrites do not get on the face and eyes.

How to sell refined gold

Considering that the price of the pure noble metal at the Central Bank exchange rate is 3,780 rubles per gram, gold refining is a profitable enterprise. Prices can be tracked on bank charts, which are updated daily. The main thing is to know how to sell the obtained metal.

Official way: refineries; gold account in the bank

Official sales are made by gold miners companies. For example, a person engaged in gold miningopens a joint-stock company, receives a license for this type of activity, and can sell the finished bullion bars to any bank, such as Sberbank.

Not quite official: jewelry dealers

Masters of jewelry always need pure gold. Creating different items, jewelers get necessary ligatures, that's why they buy precious metal in banks. They will buy refined gold with great pleasure in any currency: either in rubles or dollars. Therefore, a physical person can safely go to a jeweler in any city: St. Petersburg, Moscow or another.

Now it is not difficult to find a buyer for gold on the Internet. But you should avoid the sites of private advertisements, because illicit turnover of precious metals is controlled by the laws of the Russian Federation. It is better to turn to official sites, such as the auction of Violity: here you can buy and sell antiques, jewelry. This way the legality will be respected.

Punishment for illicit trafficking in precious metals under Article 191 of the Criminal Code

According to Article 191 of the Russian Criminal Code, people can be punished for the following actions:

- theft of jewelry;

- Purchase and sale of gold and gold jewelry;

- storage;

- transportation, shipping, any kind of transportation.

We are talking about large quantities of jewelry. It is possible to get a real prison sentence if the turnover was made with gold items worth 1.5 million and more. If the value of the transaction, the product is lower, then you can get by with an administrative penalty.

Video: Gold refining at home

A practical application of the knowledge of gold refining can be seen in this video.

Jeweler's comment

I liked the article, learned a lot of interesting things. However, it was interesting because the author of the video commenting on the process during the melting of the sediment mentioned some powder, but did not say what kind of substance, white in color. So what is this substance?