Silver itself is quite often used to coat various elements of machinery and electronic equipment. Its reuse involves pre-cleaning of the ligature. The physical steps involved in dissolution The refining of the precious metal with the help of chemicals is called refining. There are many methods to help obtain pure technical silver that can be used at home and for industrial refining.

Items containing silver suitable for refining

Much silver that can be used for technical purposes is contained in Soviet radio equipment, electrical industrial equipment. The metal was also used to cover the contacts of the following devices that had already failed:

- mine magnetic starters;

- mine substations;

- rel;

- flags (ceramic capacitors);

- temperature sensors;

- communications equipment;

- X-ray film, photographic film;

- electrical computing equipment from different periods of production.

What is refining

Silver refining is aimed at obtaining a pure noble metal. It is the process of separating it from various impurities using special technologies that is called refining. There are several different ways cleanings, which are applied in stages, require certain knowledge and skills.

Required equipment

Different methods involve the use of special equipment. These include:

- oven;

- cup-shaped crucible;

- power supply;

- burner;

- sandstone (plastic) cells;

- utensils designed to work with chemicals.

Tools for work

The following tools are also needed for the cleaning process:

- glass containers;

- glass rod;

- busbar (tube) made of copper;

- flank;

- round pliers;

- wire cutters;

- awl;

- cloth bags.

Chemical materials and raw materials

In the purification of the precious metal are also used:

- various acids;

- alkaline substances;

- water.

Silver refining methods. Step by step instructions

There are many methods aimed at separating the noble metal from the impurities at home. The most popular of these are:

- The chemical method Cleanup - is performed using acids and sodium sulfite. It is not a complicated procedure, but it does require following some rules. retrieve precious metal high quality.

- Electrolytic separation - used if there is no possibility to buy and use acids. It is the most effective cleaning method from impurities of silver nitrate.

- Acid-free refining - refining is carried out without the use of acids, after preliminary preparation of metal.

- Cupping - used for low-grade precious metal. The method requires the use of special equipment. It helps to quickly clean low-grade metal.

- Silver recovery from photographic film - used to process photographic paper, X-ray film, fluorography. It produces a small amount of technical precious metal.

Electrolytic for technical silver

Silver refining by electrolysis is the use of ammonium nitrate and sulfuric acid heated to a certain temperature. Heating of these components promotes the formation of nitric acid, which is actually able to produce technical metal.

To carry out the refining, you need:

- glass containers for acid;

- sulfuric acid electrolyte;

- saltpeter;

- sand bath;

- zinc shavings;

- salted;

- hydrochloric acid;

- hot water.

To dissolve the precious metal using this method, you will need 1 liter of aqueous electrolyte, 0.5 kg of nitrate per 100 grams of excreted metal. Dissolution will be carried out over the course of a day.

The formula for successfully dissolving silver is as follows:

- The glass three-liter container should be set on a sand bath heated by an electric stove.

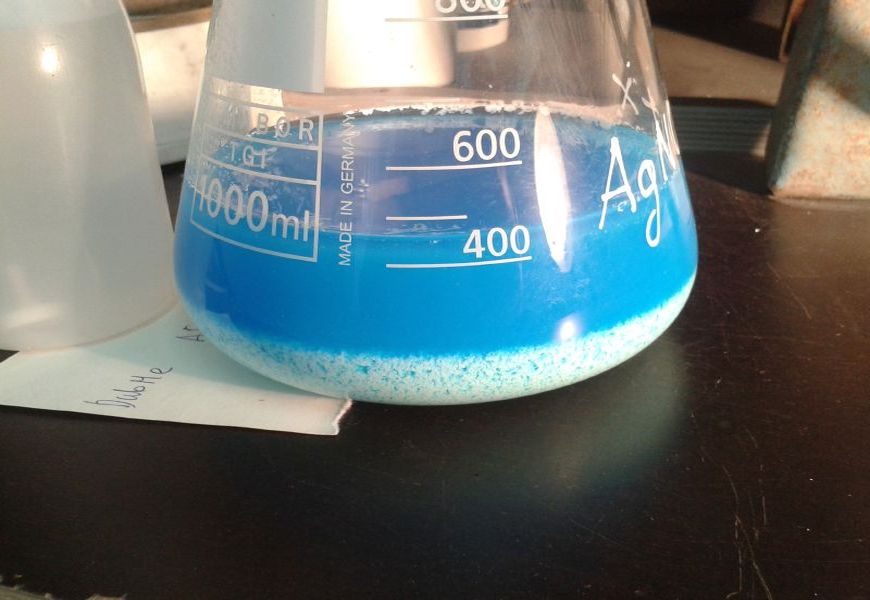

- The container is filled with 150 grams of nitrate, 300 ml of electrolyte.

- When heated, these substances begin to react. The reaction looks like boiling, with red gas released. The color of the liquid changes, turning blue.

- When the reaction stops, the rest of the chemical components are added in proportion to the amount of metal released. The elements coated with the precious metal are immersed in the solution.

- When the metal is completely dissolved, you can start making silver chloride. For this purpose, a container is filled with warm water, almost to the top. Salt is also poured into it until flakes appear on the surface.

- Now the chloride can be filtered. After separating the flakes from the liquid, hydrochloric acid is poured in. The acid should be about 2 cm above the precipitate. Zinc shavings are added to the solution as a reducing agent, which reacts with the acid, displacing the silver metal. The process is accompanied by the release of hydrogen.

- Already in half an hour after precipitation, a charcoal precipitate is formed, which is silver.

- It is necessary to check whether there is acid in the solution: to do this, the liquid is pounded with zinc shavings, which triggers a dissolution reaction. If there is no such reaction, the container should be filled with hydrochloric acid, this is necessary in order to clean the resulting metal from zinc, which makes it brittle, not suitable for further use.

- At the end of the reaction the formed metallized precipitate is washed. Now the flakes can be fused using a crucible and a burner.

Silver refining with nitric acid and precipitation with copper

Dissolution of silver in nitric acid involves the use of the following tools and materials:

- nitric acid (200 ml per 100 g of processed metal);

- zinc;

- glass container;

- graphite gas or electric furnace;

- copper;

- filter paper;

- watering can;

- fixtures For melting.

Step-by-step execution of actions:

- The part coated with the precious metal is dipped into the acid. The reaction occurs, which is accompanied by heat and red smoke with a specific smell. The acid dissolves the alloy faster if it is heated slightly. The equation of the reaction is as follows: 3Ag + 4HNO3 = 3AgNO3 + NO + 2H2O.

- Next, water is added to the resulting nitric acid solution at the rate of 2 liters per 0.5 liters of dissolved metal.

- To separate silver chloride, copper is added to the vessel. The silver precipitation takes place immediately after the copper pieces come into contact with the liquid. A metallized precipitate appears on the surface in the form of flakes. When the silver reducing agent is completely dissolved, more can be added. Further change in the color of the liquid, the solution darkens. Copper should be added until the precious metal no longer precipitates.

- Next, it is important to stand, filter and wash the purified metal. The precipitate is rinsed with hot water. Repeat rinsing until the water in the pot is clear. Then you can begin drying the flakes. This leaves a metallized gray powder that can be melted down further.

Lead baptism

It is possible to obtain precious metal from a low-grade alloy by lead smelting. To separate the solder you need a special furnace and crucible that resembles a cup. Lead is a magnet that attracts fluorides to itself and separates them from silver during the melting process.

The use of a special furnace covered with marl is necessary so that lead oxide, which is released from the molten metal, does not escape outside with the air.

When the refining is completely finished, the surface of the vessel will be covered with an iridescent film, through which you can see a silver glow.

Acid-free refining

For this method of refining, the contacts of electrical devices are used. They are thinned to the maximum by any convenient means. It is important that the entire refining process be carried out in fresh air or in the presence of a good hood.

You'll need:

- oven;

- sand bath;

- special dishes;

- glass rod;

- filter paper;

- a vessel for rinsing;

- salts (2 parts ammonium chloride, 1 part nitrate);

- concentrated ammonia;

- copper wire.

The process is as follows:

- Prepare reagents, weigh and mix.

- A bath and a vessel with contacts covered in salts are placed on the stove.

- The container is heated, periodically stirring the contents. After about 10 minutes a reaction begins to appear. A white gas is released.

- When the reaction stops, the furnace can be turned off. The resulting solution should be cooled.

- The contents of the dish is well washed with water, filtered through paper.

- When only a metallized precipitate remains on the paper, ammonia is poured over it, which will release silver chloride without additives.

- A copper wire is dipped into the prepared solution, which pushes out the precious metal. The resulting precipitate is again washed with water, dried and fused.

Refining from photographic film

Silver is used not only in electrical engineering, but also in medicine. The metal is used not only for medical equipment, but also in consumables, such as films for X-rays and fluorography. The removal of the silver layer is usually carried out at waste collection points that contain precious metals.

The film is coated on both sides with silver bromide. It is soaked in a solution of chlorine and lime. After 10 minutes, discolored pieces of film remain and can be removed. The resulting solution has a distinctive milky hue. The solution should be allowed to stand for 3 to 4 hours. To speed up the dissolution process, you can add sulfuric acid alumina to the liquid. After settling, the sludge can be filtered, washed and dried.

The essence of silver refining at home with electrolyte

Electrolysis silver involves the use of a direct electric current, under the influence of which charged silver particles are moved from the cathode to the anode. The positive electrode in this method is a scrap silver and the negative electrode is a silver plate.

Electrolysis involves the use of the following devices:

- current transformer;

- clips;

- a vessel with electrolyte;

- voltage tester.

Step-by-step execution of actions:

- To the positive electrode you have to connect the radio component that you plan to clean. A plate is attached to the negative contact.

- The transformer is plugged into the power grid. The whole process lasts no more than 30 minutes. All this time the voltage must be monitored.

- The presence of current is the main condition under which silver plating without impurities gathers at the anode.

This method is considered the easiest and fastest because it does not involve washing the metal or using large amounts of chemicals.

Precautions for home metal mining

Regardless of whether cleaning is carried out in industrial or at homeThe following safety precautions must be observed. The necessary precautions are:

- the presence of good ventilation in the room;

- Use rubber gloves, protective clothing and goggles to prevent chemicals from getting on your skin;

- When working with acids, use a respirator;

- If it is necessary to dilute the acid, it is poured into the water, but not vice versa.

How much is refined silver

Refined silver, which is close to 999 purity, can be sold for about 40 rubles per gram.

Where to sell a trophy

Obtained by refining Precious metal can be handed in at gold and silver collection points. The price may vary depending on the point that is ready to buy scrap, the quality and quantity of the obtained precious metal.

Technical silver applications

Recently, the demand for the technical precious metal has increased significantly. Previously, the sale of radio partsThe only option that existed was contact. Today, many people have learned how to obtain silver at home, which can be sold to collection points or reused.

The metal is considered technical only because it is extracted from scrap through refining. In terms of its properties and characteristics without impurities, it refers to silver mined in natural conditions.

Acceptance of purified technical precious metal is priced substantially higher than the price of scrap containing the precious metal. Secondary raw material is subsequently used for coating boards, contacts, switches, relays and other parts of equipment. Such a coating must have high thermal and electrical conductivity, be resistant to corrosion and easy to process.

Летние домики для дачи на сайте village-comfort.ru

Video: silver refining methods

Question and answer section

How to dissolve silver?

- chemical dissolution;

- electrolytic refining;

- lead baptism;

- purification of silver with copper;

- silver production from the film.

Cleaning silver from impurities at home, how?

Jeweler's comment

It is important to remember that each method of silver refining has its own peculiarities. When using home refining, the following mistakes are often made:

- When large amounts of nitric acid are used for cleaning, nitric oxide is released. Other, unforeseen reactions can also occur.

- Using electrolysis as a cleaning method, vertical positioning of the electrodes opposite each other can weaken the separation process. In this case, the effect of the electrolyte is significantly weakened.

- Excessive current during electrolysis can release silver oxide, causing the metal to become highly oxidized and black.

- Failure to comply with mandatory safety rules and requirements leads to chemical burns, poisoning by poisonous vapors, and other health problems.